PTP Smart Warehouse Software

The PTP (Pallet-To-Person) smart warehouse software serves as the core control system for smart warehouses. This smart middleware integrates storage, handling, and picking policies, facilitates multi-device collaboration, and incorporates a range of robotic scheduling algorithms. It offers features such as warehouse business operations, warehouse equipment monitoring and management, and smart equipment maintenance for the users.

GENERAL INQUIRY

Please fill out the form below and click the "Submit" button. We will contact you once receive your inquiries.

Software Architecture

Key Features

Simple Deployment

Different workflows can be quickly combined through the configuration, without the need for secondary development, the system can be launched with one key, rapid deployment and use

Open Flexibility

The system standard interface can be docked ERP, MES, SAP and other types of software systems also support different types of equipment, including film wrapping machine, depalletizing, robots, agv and other types of intelligent equipment, data interoperability, to enhance the smoothness of the operation.

High Density, High Efficiency

It supports a variety of strategy options such as first-in-first-out, combined tray, etc. It optimizes the use of warehouse aisles according to the cargo situation and improves the utilization rate of storage capacity; according to the task situation, it can reasonably dispatch the distribution of shuttles.

Area-Wide Information Interoperability

Management of materials from warehousing to shipment of information in all areas, to eliminate information silos, improve energy efficiency; tracking pallets in each piece of equipment, to ensure that the link is smooth, to enhance the stability of the system.

GENERAL INQUIRY

Please fill out the form below and click the "Submit" button. We will contact you once receive your inquiries.

PTP Software

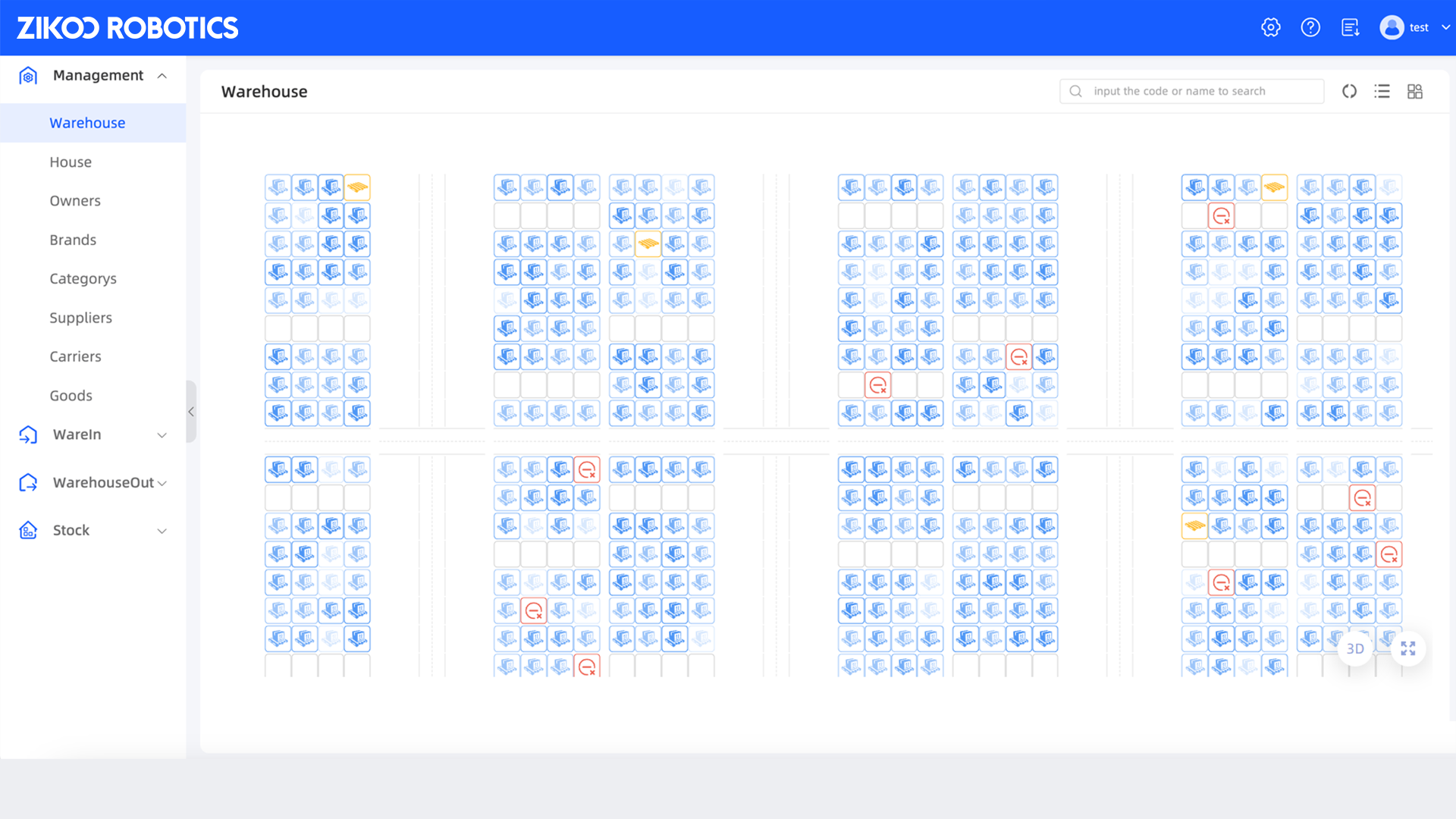

IWMS

Intelligent Warehouse Management System

It empowers smart warehouse material management systems for various scenarios, including procurement, production, and sales. Different types of warehouse workflows can be organized according to specific business scenarios. Business personnel create inbound and outbound orders using the IWMS system. The system then automatically identifies the appropriate workflows and generates inbound/outbound tasks in the warehouse.

The system is designed to flexibly integrate through modularization, working in conjunction with a variety of containers, robots, and workbenches to enable smart operations such as material storage, handling, picking, and sorting. The system also offers comprehensive statistical data and BI modules to aid the warehouse in making swift decisions and achieving precise management.

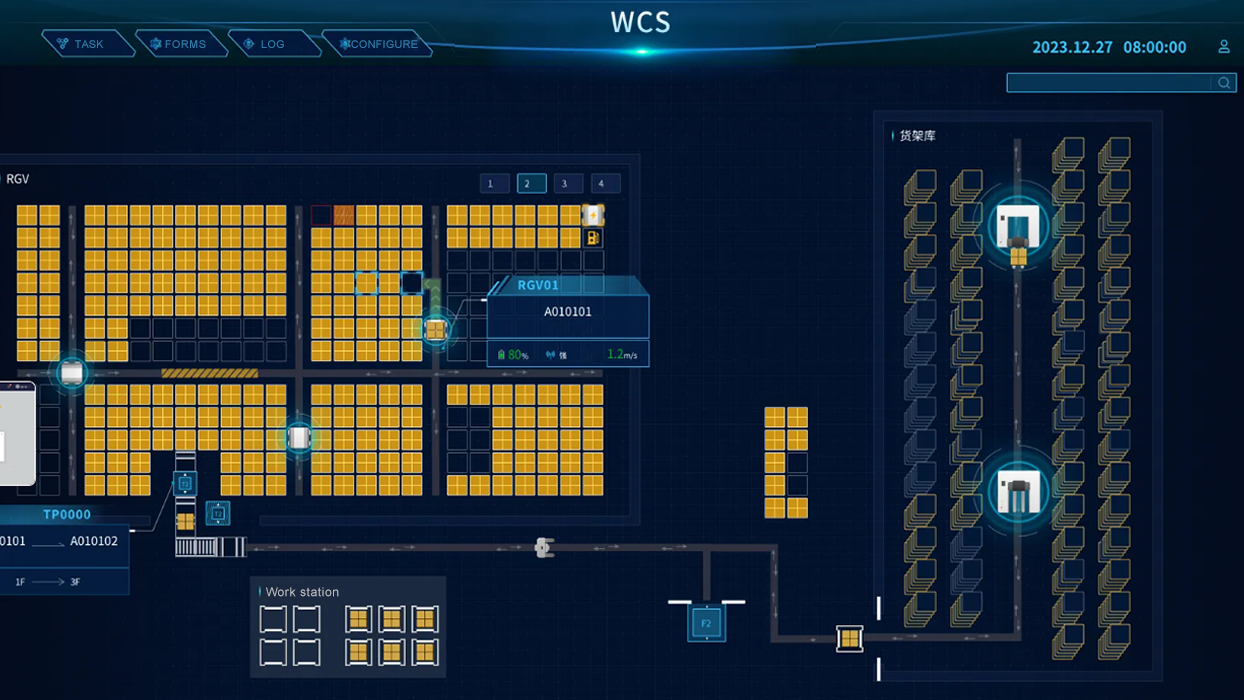

IWCS

Integrated Wideband Communication System

It is a scheduling system designed to execute automated task breakdowns and collaborative operations across various devices. Through the use of core algorithms, tasks such as pallet handling, material sorting, and picking are transformed into collaborative processes among various robots. Operational efficiency can be maximized by smartly organizing device management procedures.

In addition, the system is equipped with storage management and operation monitoring features. It can automatically match available devices and optimize the scheduling of the global device layer for maximum efficiency, stability, security, among other aspects.

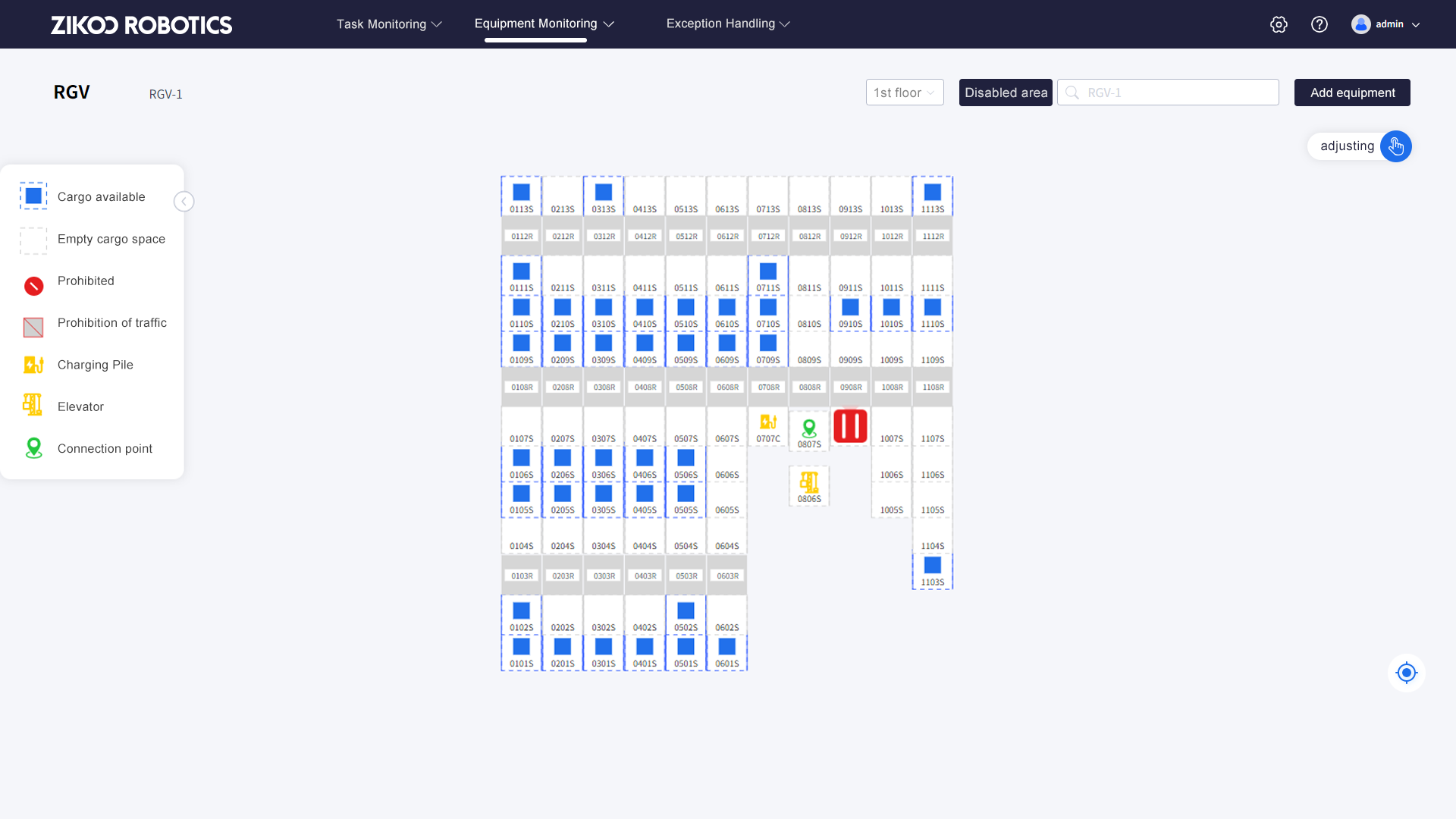

RMS

Intelligent Warehouse Management System

The system features built-in simultaneous scheduling for multiple robots. It uses a spatial model algorithm for conflict detection to enable shuttles following, congestion detection, deadlock avoidance, obstacle avoidance and other logics. A time window heat algorithm is used to predict the spatial and temporal positions of shuttles, allowing for optimal path planning and efficient operation of multiple shuttles.

By employing a smart production scheduling algorithm, various types of robots can perform collaborative tasks, resulting in smart handling, connectivity, layer changing, and charging.

GENERAL INQUIRY

Please fill out the form below and click the "Submit" button. We will contact you once receive your inquiries.

IWMS Creative Advantage

Autonomous scheduling of task flows

Process Modules Arbitrarily Programmed Quickly match the new business

Hotness analysis of goods/tasks

Idle stocking, lane planning Autonomous decision-making for mixing and non-mixing

Fine management of materials across the region

Material lifecycle management Inventory interoperability, Eliminating information islands

GENERAL INQUIRY

Please fill out the form below and click the "Submit" button. We will contact you once receive your inquiries.

IWCS Creative Advantage

Quick combination of multiple equipment

3-minute quick deployment for equipment expansion

Multi Equipment Task Balance

Dynamic allocation of equipment according to the number of tasks Dynamic adjustment of routes according to equipment status

Equipment Parallel Scheduling

Plan moves in advance Reduce waiting time

GENERAL INQUIRY

Please fill out the form below and click the "Submit" button. We will contact you once receive your inquiries.

RMS Creative Advantage

Flexible Combination Cluster Route Planning

Route elapsed time penalty (Heat map+ Route Planning) Avoid blocking and eliminate deadlocks

Dynamic Autonomous Group Charge

Full Database of Information Integration Charge time strategy and location strategy

Multi-scenario analysis Intelligent Task Decision Making

Planning Shuttle Floor Changes Failure task switching

GENERAL INQUIRY

Please fill out the form below and click the "Submit" button. We will contact you once receive your inquiries.

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-13851470374