The Smart Upgrade of Japanese Cold Storage Facilities

As the scale of the cold chain logistics market gradually expands, the demand for specialized cold chain storage, such as fresh food and agricultural products, is also on the rise.

GENERAL INQUIRY

Please fill out the form below and click the "Submit" button. We will contact you once receive your inquiries.

Achievements

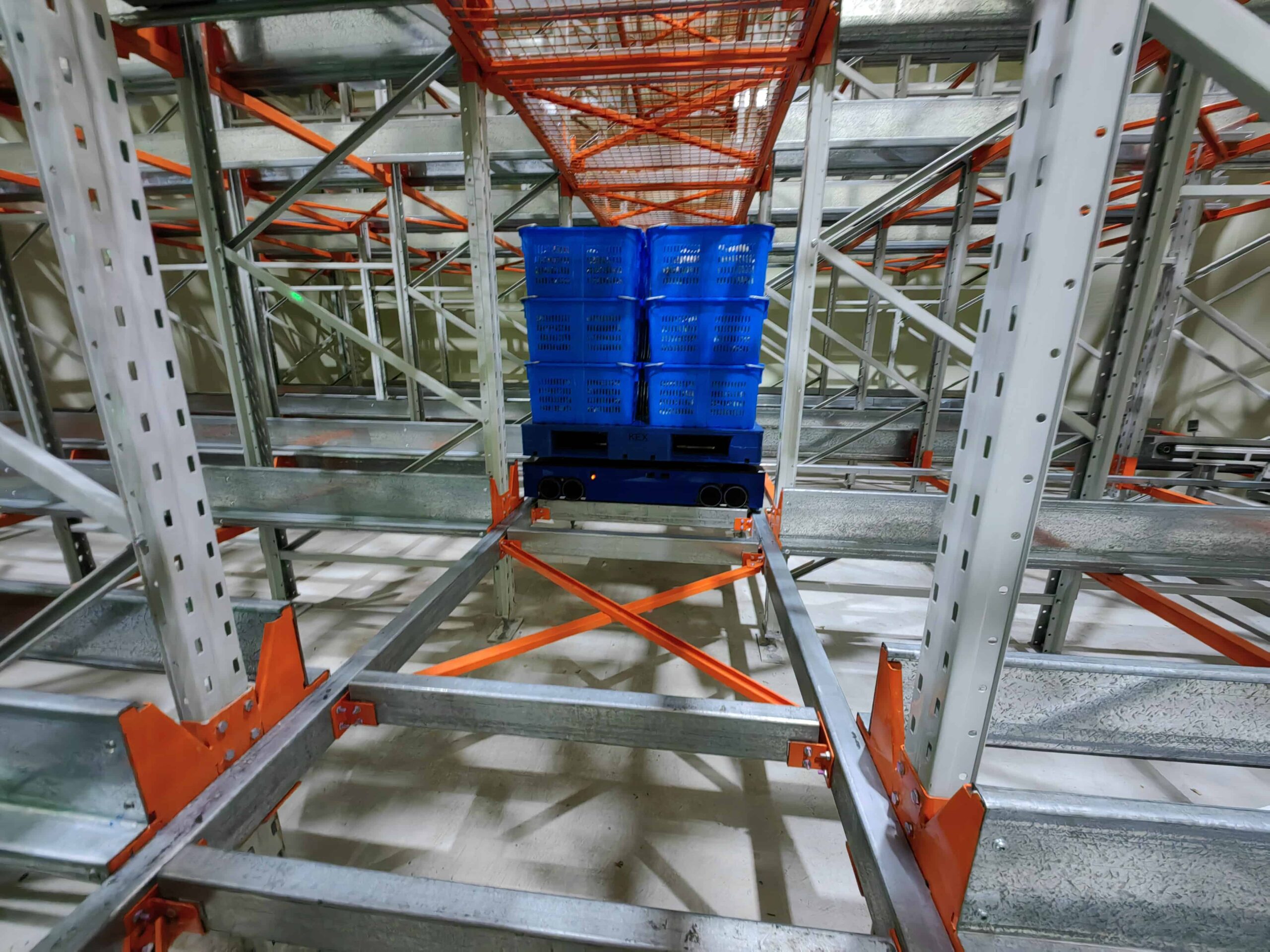

- Establishment of a multi-deep cold storage dense automated facility, resulting in a 50% increase in space utilization.

- Operation at temperatures as low as -25°C with a speed of 1.4m/s, doubling efficiency and providing robust support for food preservation.

- Fully automated and unmanned operation, reducing personnel access and ensuring a stable temperature and humidity environment within the cold storage.

- Battery life of 6-8 hours on a full charge, effectively replacing manual labor and addressing the labor shortage issue in cold storage.

Zikoo's Solution

- Construction of a 325 square meter cold storage facility with 4 levels and 296 storage positions.

- Deployment of three cold chain automated guided vehicles (AGVs) and a comprehensive software system including Warehouse Management System (WMS), Warehouse Execution System (WES), Warehouse Control System (WCS), and Robotic Control System (RCS).

- Use of pallets with dimensions of 1100mm x 1100mm x 130mm.

Challenges

- Low space utilization.

- Low efficiency of manual operations.

- High requirements for warehouse stability and cleanliness.

- Adverse working conditions affecting health and difficulty in hiring workers.

Project Background

As the scale of the cold chain logistics market gradually expands, the demand for specialized cold chain storage, such as fresh food and agricultural products, is also on the rise. During the pandemic, various fresh food platforms experienced explosive growth in business volume, driving a significant surge in cold chain fresh food warehousing. Major food companies have also raised higher requirements for the informatization of cold chain logistics. As a result, the cold chain logistics industry has been thrust into the spotlight, and cold chain warehousing is urgently facing the need for intelligent and digitized transformation.

Industry Case Study

In recent years, with increasing public concern for food health and safety, the fresh food cold chain industry has experienced rapid growth, with its market size expanding annually. However, the COVID-19 pandemic has posed significant challenges to food storage and distribution, including staff shortages due to quarantine and safety risks from human contact. These challenges have accelerated the transformation towards unmanned and intelligent cold chain warehousing. Zikoo Robotics has provided a comprehensive intelligent warehousing solution to a Japanese food company, achieving significant advancements in automation and intelligence in cold storage. This transformation has doubled storage efficiency and increased storage utilization by 50%.

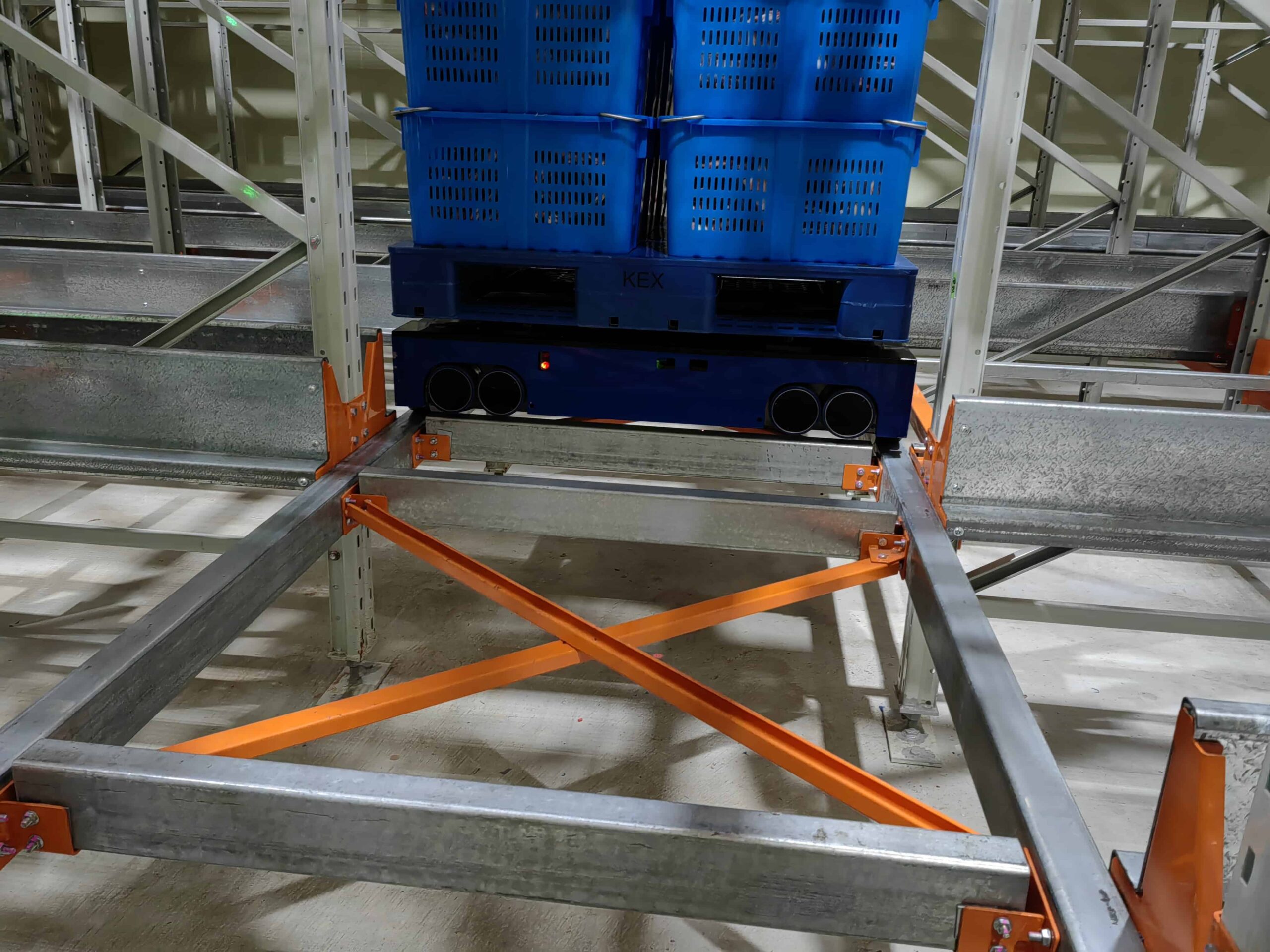

A notable element in the Japanese project is the adoption of Zikoo Robotics’ ZK-R series of intelligent shuttle vehicles specifically designed for cold chain operations. These vehicles, distinct from those used in ambient temperature settings, are equipped with cold chain-specific kits and are specially designed for the unique conditions of cold chain environments. Capable of operating efficiently, smoothly, and safely in temperatures as low as -25°C, they feature four-way flexible movement, intelligent autonomous handling, and collaborative operation among multiple vehicles.

The ZK-R series is equipped with special low-temperature batteries suitable for cold products, offering up to 8 hours of battery life and a maximum load capacity of 2000kg. Available in three sizes, these vehicles can automatically schedule charging, eliminating concerns about power supply. Having undergone over 70 rigorous testing procedures, these high-standard manufactured vehicles are now used in numerous low-temperature warehouses worldwide.

Zikoo Robotics is a leading provider of pallet storage solutions, boasting comprehensive research and development capabilities across the entire value chain, including robot bodies, core algorithms, operating systems, and business systems. The company is dedicated to providing customers with efficient, high-density, flexible, and rapid-delivery intelligent warehousing solutions. To date, Zikoo Robotics has launched a range of robots and intelligent systems, serving industries such as machinery, new energy, home appliances, cold chain, food, and home furnishings. With a leading reputation in the industry, the company is a rising force in the warehouse robotics sector, continuously promoting the digital and intelligent transformation of enterprise storage.

Related Products

R-Bot

Four-Way Pallet Shuttle

H-Bot

High Speed Elevator

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-13851470374