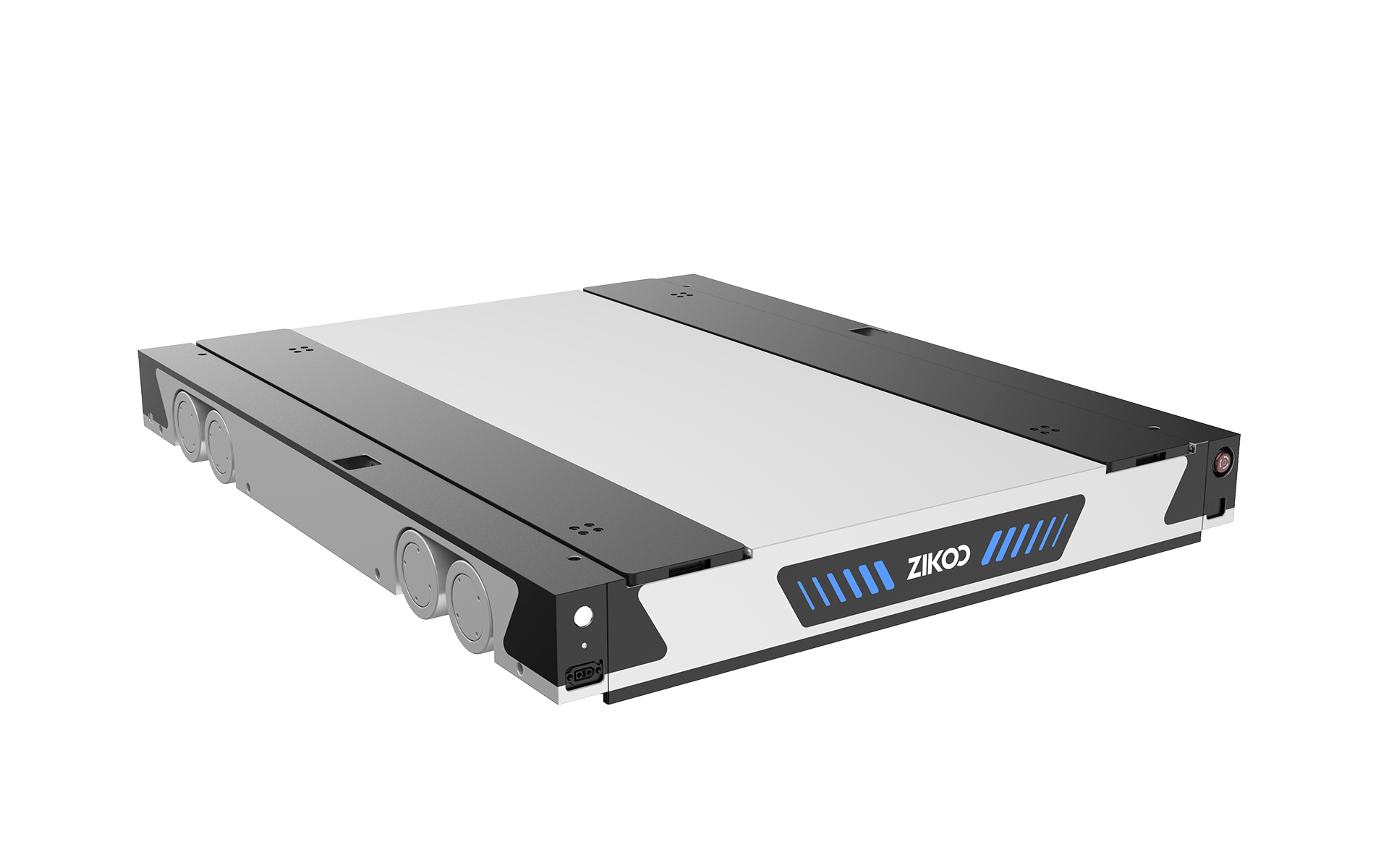

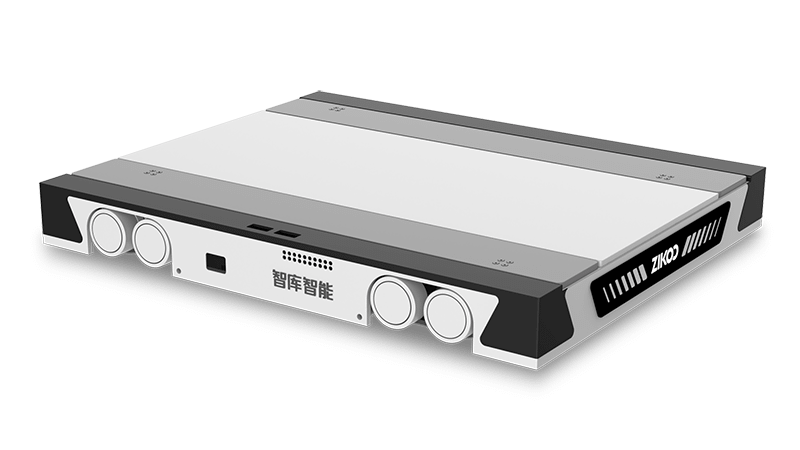

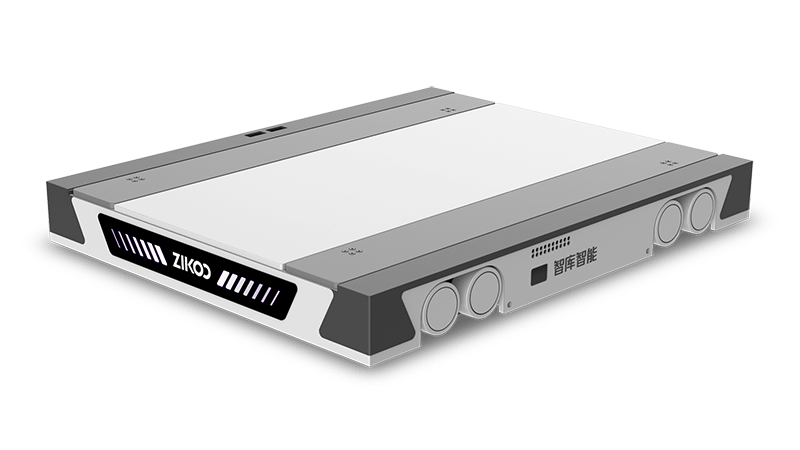

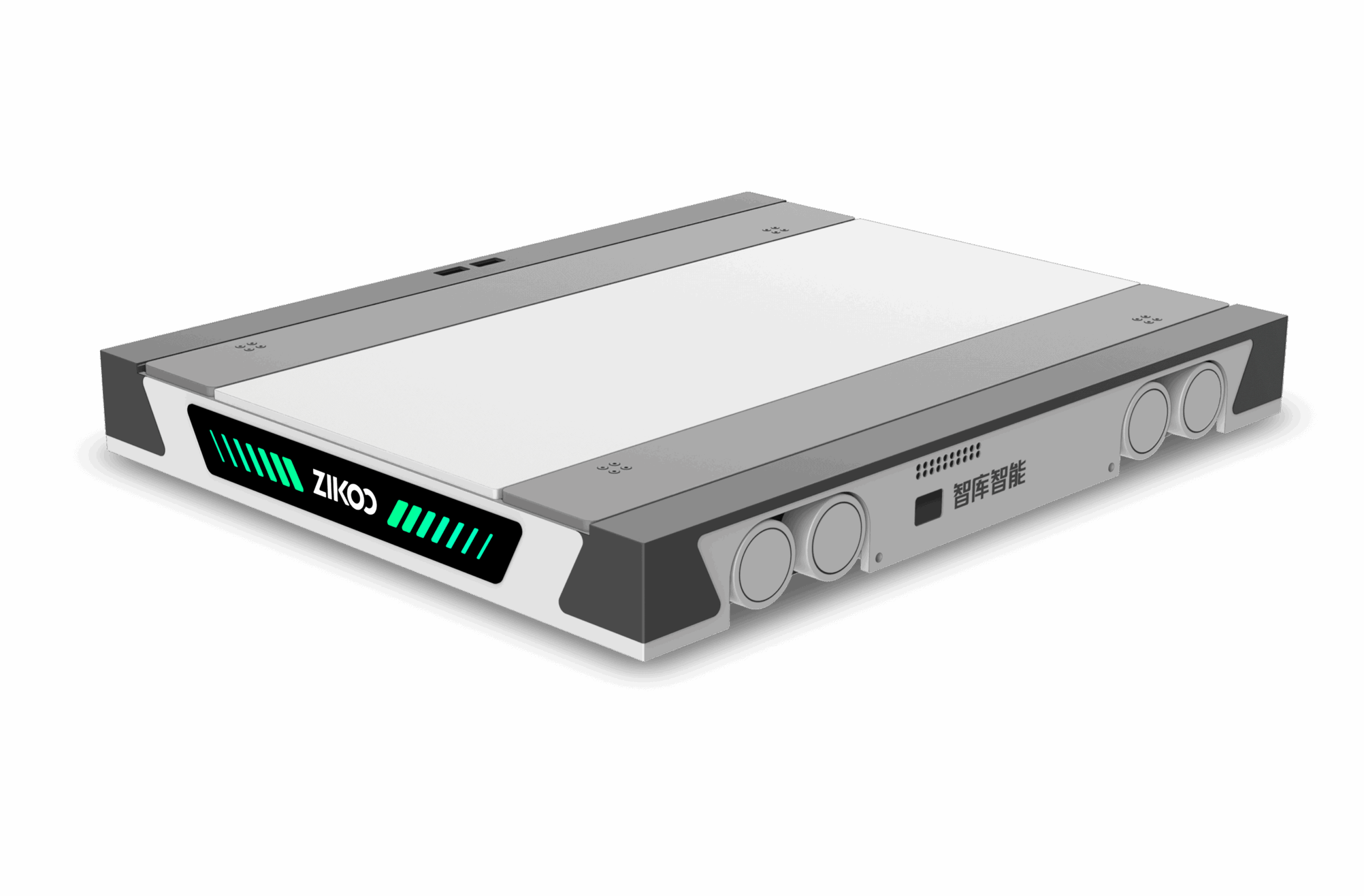

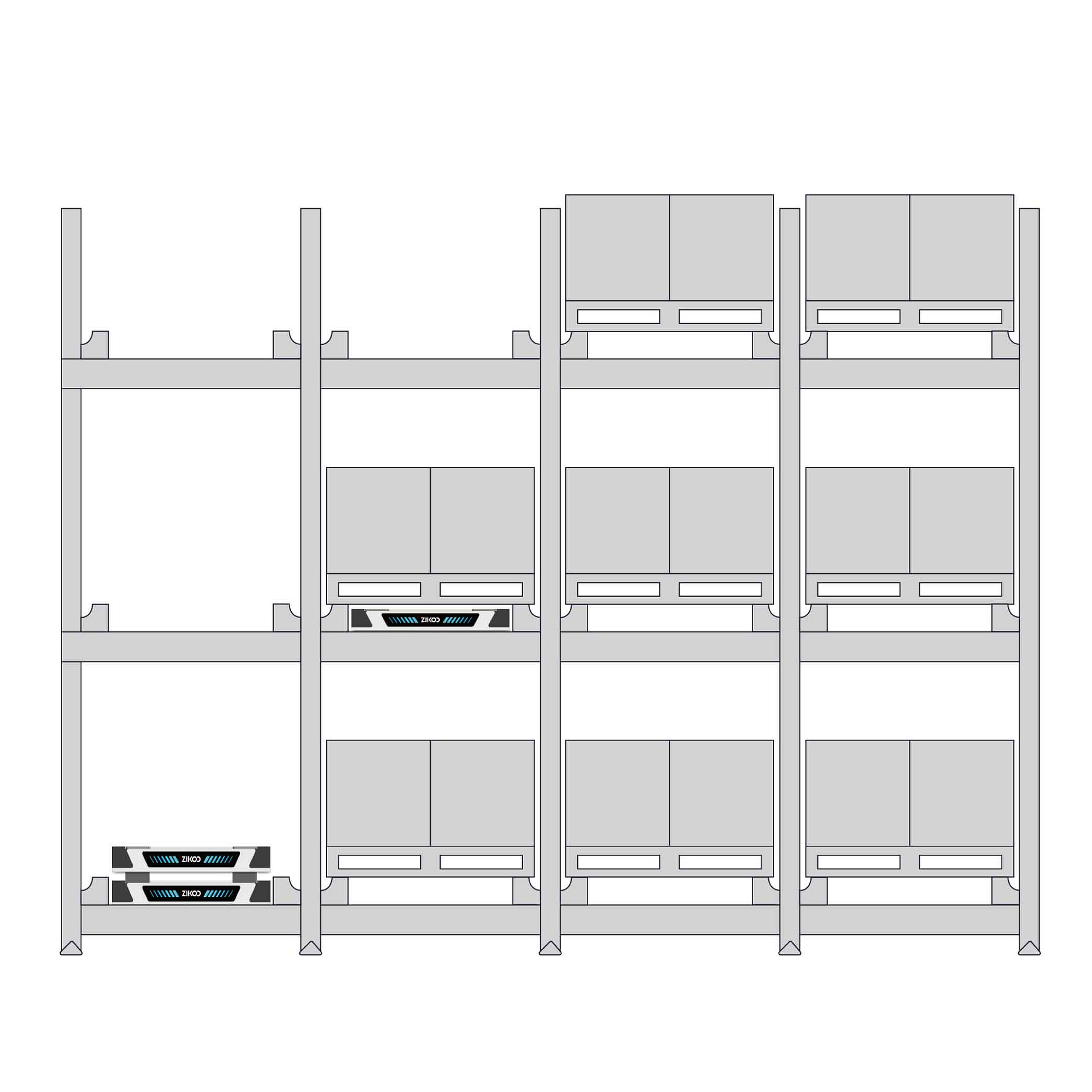

Four-Way Pallet Shuttle

R-bot Optimizes Dense Pallet Storage

Standard type | American type | Japanese type| Heavy-duty type| Heavy load large pallet type

The R-bot Four-Way Pallet Shuttle actively manages high-density “pallet-to-person” storage solutions. It travels flexibly in four directions, handles pallets autonomously, and coordinates with multiple shuttles to boost warehouse efficiency. The system seamlessly integrates with equipment such as H-bot vertical two-way shuttles, adapting flexibly to the needs of various industries. By excelling in pallet storage and picking operations, the R-bot Four-Way Pallet Shuttle empowers modern automated warehouses.

125mmThickness |

1500kgRated load |

1.6 m/sDriving speed |

2.5sReversing time |

Technological Innovation

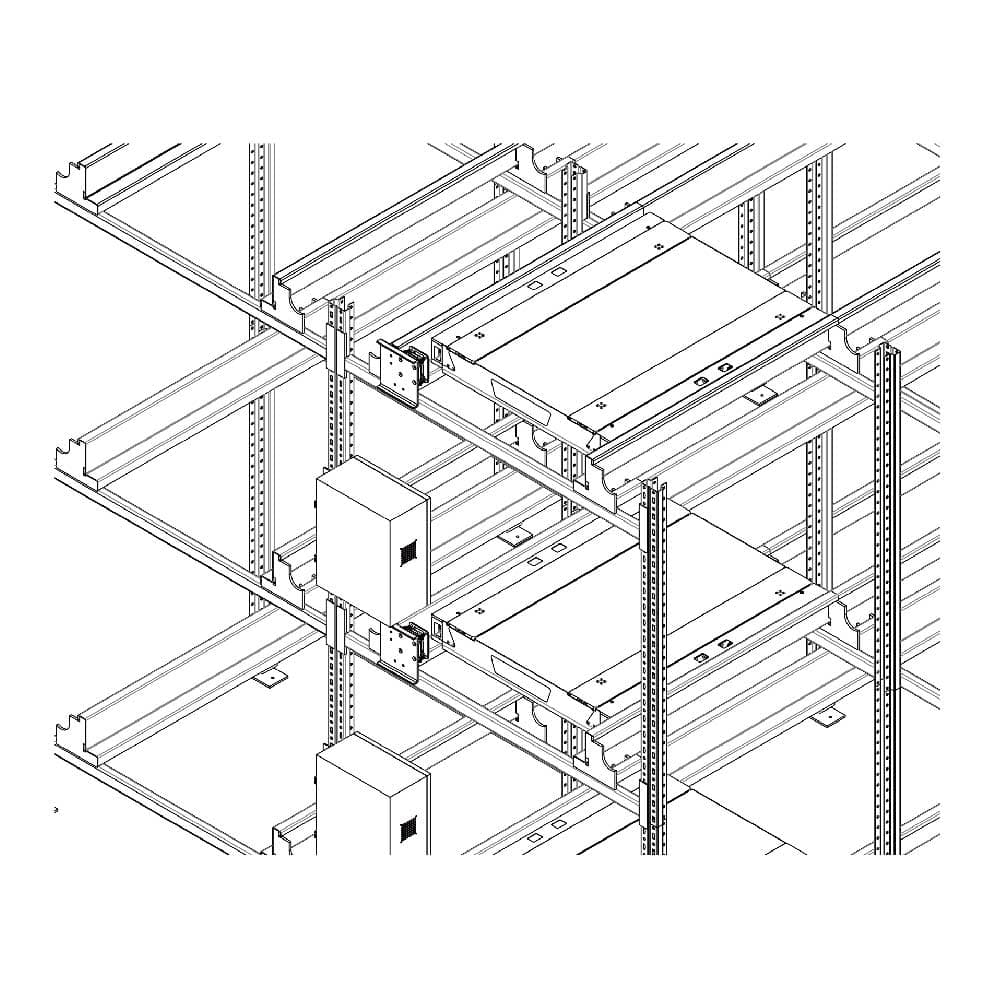

Fully mechanical structure

- Full gearbox mechanical transmission, long life and maintenance-free

- Thickness of the body is only 125mm, carrying 1.5 tonnes.

Core brain

- Fully self-developed IP68 rated industrial controllers

- Higher computing power and faster response speed

Maximum speed

- Empty load speed 1.6m/s

- Full load speed 1.2m/s

- Lifting time 1.5s

Accurate positioning

- Positioning accuracy ±1mm, support different size pallets mixing storage in the pallet lane

- RFID + magnetic induction + encoder positioning, high robustness

Scene adaptation

- Cover -25℃~45℃ temperature environment

- Suitable for various pallet sizes,customizable

Reliable energy

- Double BMS intelligent charging protection, energy security

- Extra large battery capacity, 10h long battery life

Network stability

- High performance wifi6 for fastest roaming switching

Safety protection

- Ultra-long distance laser obstacle avoidance, power system STO function

- Single 64-dot matrix pallet skew detection, anti-fall tilt

Product Values

Flexible

The Four-Way Shuttle can access any location within the stereoscopic warehouse without being restricted by fixed paths, making it suitable for a variety of complex scenarios.

Smart Scheduling

It can be integrated with elevators, conveyors, and other equipment, allowing for the efficient scheduling of multiple vehicles on the same floor, as well as smart scheduling among various devices.

Efficient Handling

A highly intelligent design is used to enable auto goods handling and conveying, as well as switching of aisles and layers, thus ensuring efficient operation.

Dense Storage

Ideal for dense storage of pallets, significantly enhancing space efficiency and reducing land costs.

R-bot four-way shuttle product parameters

Model

Weight

Rated load

Body dimensions

Applicable pallet sizes

-

Kg

Kg

mm

mm

R1200B

270

1200

L1000*W972*H125

1200*800~1000

R1200A

265

1200

L1192*W840*H125

1016*1219

R1500J

270

1500

L1192*W900*H125

1100*1100

R1500B

275

1500

L1192*W972*H125

1200~1600*1000~1200

R2000B

400

2000

L1250*W1300*H150

1600~2000*1200~1400

Navigation

Positioning accuracy

Empty/full load speed

Maximum acceleration

Reversing time

Lifting time

-

mm

m/s

m/s²

s

s

RFID + Magnetic Induction + Encoder

±1

1.6/1.2

2

2.5

1.5

RFID + Magnetic Induction + Encoder

±1

1.6/1.2

2

2.5

1.5

RFID + Magnetic Induction + Encoder

±1

1.6/1.2

2

2.5

1.5

RFID + Magnetic Induction + Encoder

±1

1.6/1.2

2

2.5

1.5

RFID + Magnetic Induction + Encoder

±1

1.35/1.0

1.5

3.5

2

Applicable temperature

Battery capacity

Duration at full charge

Full charging time

Type of batteries

℃

V/Ah

h

h

-

-15~45 | -25~0

51.2V/40Ah | 51.2V/30Ah

8~10 | 6~8

1.2 | 2

Lithium-iron phosphate battery

-15~45 | -25~0

51.2V/40Ah | 51.2V/30Ah

8~10 | 6~8

1.2 | 2

Lithium-iron phosphate battery

-15~45 | -25~0

51.2V/40Ah | 51.2V/30Ah

8~10 | 6~8

1.2 | 2

Lithium-iron phosphate battery

-15~45 | -25~0

51.2V/40Ah | 51.2V/30Ah

8~10 | 6~8

1.2 | 2

Lithium-iron phosphate battery

-15~45 | -25~0

51.2V/40Ah | 51.2V/30Ah

6~8 | 5~7

1.2 | 2

Lithium-iron phosphate battery

Certificate type

-

CE/UL

CE

CE/UL

CE/UL

CE/UL

Scenario customisation::Cold Chain Model

- The lithium battery specialized for low-temperature environments ensures stable operation at -25°C / The combination of RFID and laser positioning facilitates easy maintenance

- Enhanced security protection with a special PCBA coating / Low-temperature charging port design

- It is highly durable, with a battery life of 6-8 hours, and supports auto charging

- A high level of intelligence, featuring smart operation/scheduling/power management

Scenario customisation:New Energy Model

- Anti-static design

- The wheels are fully cushioned with rubbera

- The entire vehicle is devoid of materials like copper, zinc, nickel, and lead, and is dust-proof

- The structural components are blackened and the racks are stainless steel

Functional Module

Emergency rescue

With specialized rescue tooling, a malfunctioning shuttle can be lifted, removed from the storage rack and transported to a repair facility by coordinating with other shuttles. This process is both streamlined and efficient, enabling the rapid completion of rescue operations in just 10 minutes.

The modular design enables rapid fault diagnosis within 5 minutes. With readily available spare parts, damaged components can be replaced in 20 to 60 minutes, allowing the shuttle to return to service promptly.

Charging pile

The charging stations feature a connector designed for over 100,000 plug-in cycles, ensuring safety, stability and reliability.

The independently developed charging strategy accommodates a wide range of temperatures, from -25°C to 45°C, enhancing charging safety. Real-time monitoring capabilities cover the status of the charging stations, and include protective measures against short circuits, overload, overheating, overvoltage and overcurrent.

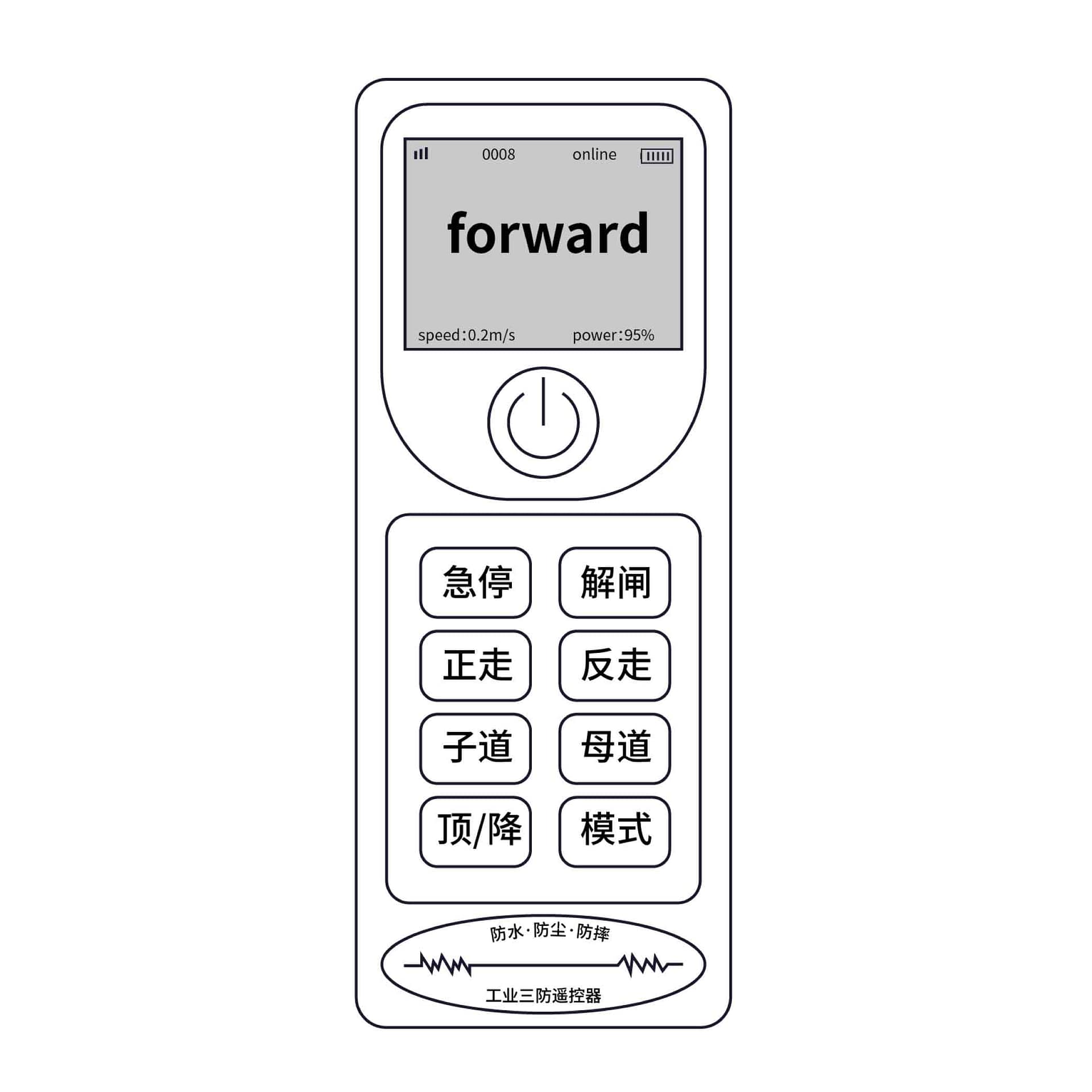

Remote controls

Operating independently of WiFi networks, our remote control uses a long-distance communication solution that ensures extended transmission ranges and improved penetration within storage racks.

It features a status display and a user-friendly interface for easier interaction. The remote control system can connect to multiple devices and only requires one unit per warehouse to manage them all.

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-19941778955