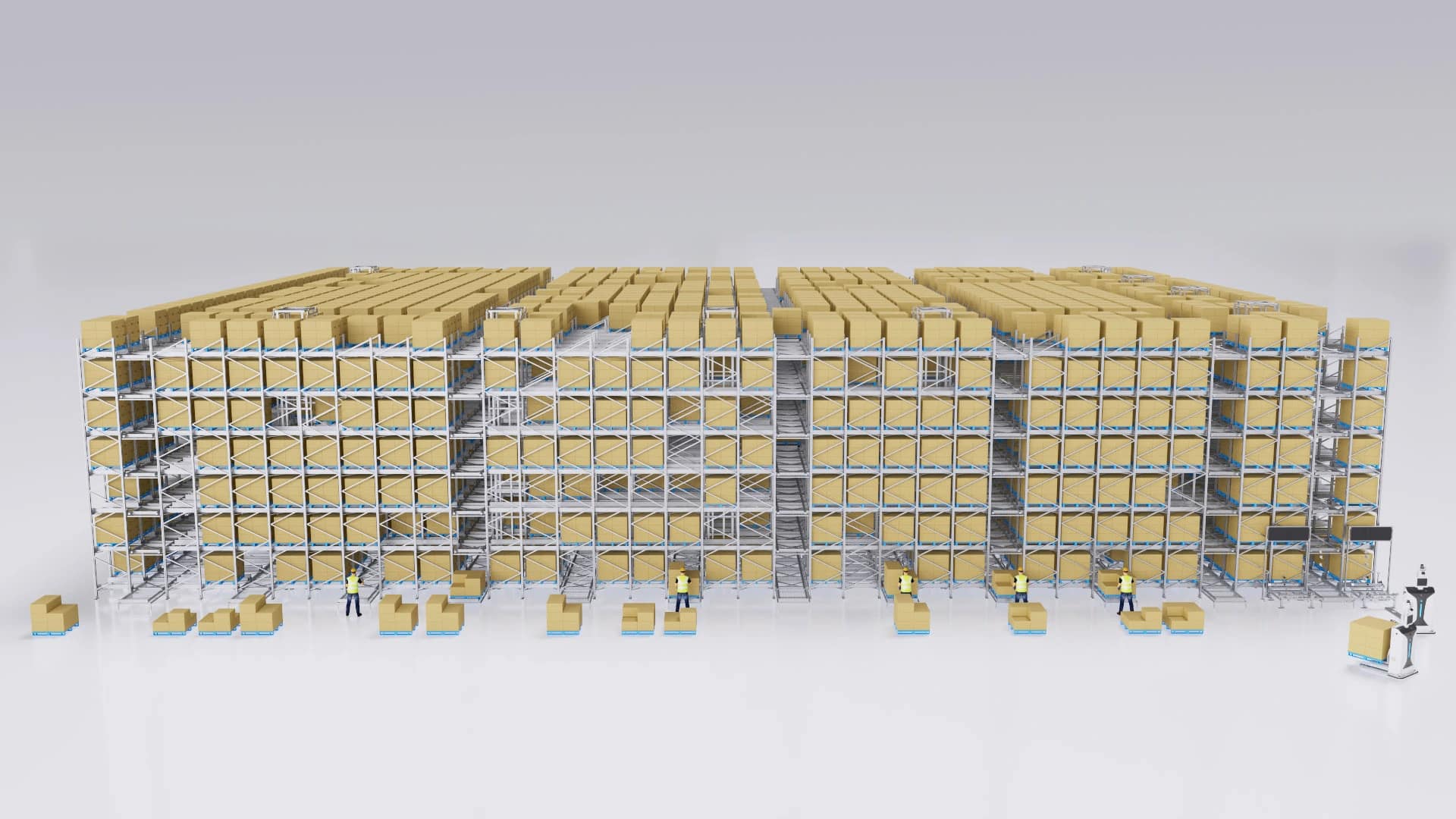

Six-Way Shuttle Storage & Picking System

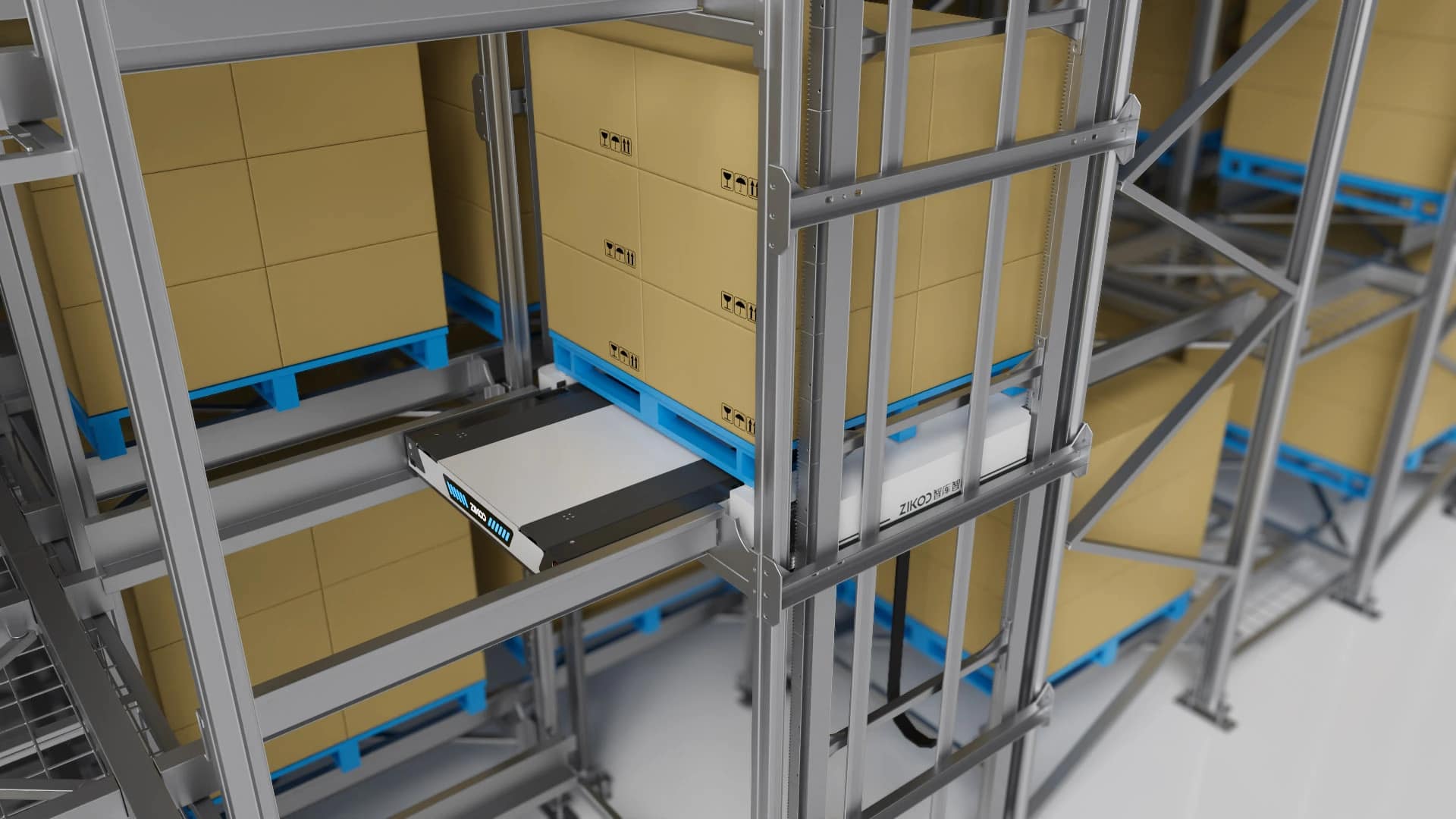

R-bot + H-bot, High-Efficiency Pallet Shuttle System for Automated Warehouse Storage

The R-bot four-way shuttle actively enters and exits the H-bot vertical two-way shuttle, enabling cross-floor handling and flexible setup of caching and picking positions at inbound and outbound points. By deploying the H-bot at any location in the warehouse, this Six-Way Shuttle Pallet System supports high-density, high-throughput pallet storage and picking operations. Unlike traditional programs, it eliminates the need for conveyor lines, significantly shortens delivery cycles, reduces operation and maintenance costs, and delivers an efficient, automated warehouse storage solution for modern industries.

The Advantages of R-bot+H-bot Six-Way Shuttle Storage & Picking System

Building on the Six-Way Shuttle Dense Storage System, we upgraded the program by combining the R-bot four-way shuttle with the H-bot vertical two-way shuttle to create an innovative storage and picking solution. We configure caching and picking positions at warehouse entrances and exits, optimize rack-side picking, and design travel aisles to minimize direction changes and handling distance. We plan racks with one or multiple layers at varying depths and channels, enabling upper-level storage and lower-level picking while maximizing storage density and picking efficiency. This automated pallet shuttle system serves high-density storage and integrated picking scenarios and is ideal for industries such as 3PL, retail, e-commerce, footwear, supermarkets, and FMCG, where efficient storage plus picking is critical.

Increase in storage capacity

- Rack “1 layer” and “2 layers and above” can be planned with different depths and aisles, realizing top storage and bottom picking, making full use of the space on the upper layer, and increasing the storage capacity by 200%+.

Increased efficiency

- Innovative storage and picking integrated program, in the entrance and exit of the warehouse according to the need to set up additional cache, picking position, warehouse side picking, travel aisle out of the warehouse, the minimum number of changes in direction, the shortest handling distance, to achieve the entry and exit of the warehouse efficiency and the efficiency of zero picking to improve 300% +.

Flexible lifting

- The number of equipment can be flexibly configured according to the number of SKUs and the requirements for picking efficiency, and the six-way shuttle can also be flexibly increased or decreased according to changes in business requirements.

Fast revenue High ROI

- Six-way shuttle storage and picking innovative solutions, from storage to picking one-stop delivery, taking into account the picking efficiency and storage density, greatly saving labor costs, saving storage area to reduce land costs, high throughput can be realized quickly revenue.

Applications

Scenarios

Industries

Composition

Connect with our experts to receive customized robotics solutions

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-19941778955