Smart Warehousing on the Fast Track

ZIKOO Robotics Empowers Building Materials Manufacturer with Four-Way Shuttle + Digital Twin Solution

In the building materials industry, where bulk bags and jumbo sacks are the primary forms of raw material packaging, traditional floor stacking has become increasingly inadequate for the demands of modern, high-efficiency, high-precision manufacturing.

In response to China’s “Smart Manufacturing” strategy and the industry’s growing need for intelligent warehousing, a leading domestic building materials enterprise partnered with ZIKOO Robotics to deploy a next-generation intelligent dense storage system powered by four-way shuttles and digital twin technology. This solution significantly improves storage efficiency and operational accuracy—laying the foundation for a smart, sustainable, and flexible modern factory, and accelerating the company’s transition toward high-quality development.

Achievements

- Storage density dramatically increased, with over 3,000 pallet positions to accommodate diverse SKUs and packaging formats.

- Inbound/outbound efficiency improved by approx. 35%, with precision handling capacity of up to 44 pallets per hour.

- Full digital twin integration ensures system visualization, traceability, and continuous optimization.

- From design to go-live in just 80 days.

- Fully unmanned operation minimizes human error and reduces O&M costs.

Project Background

As a top-tier manufacturer of industrial-grade building materials, the client specializes in products packaged in jumbo sacks and bulk bags. The legacy warehouse relied on manual stacking and forklift operation, which led to several persistent challenges:

-

Disorganized material placement and wasted floor space

-

Packaging wear and product degradation due to improper stacking and environmental exposure

-

High error rates in order picking and difficulties with stocktaking

-

Limited scalability to support future production expansion

To overcome these limitations and align with its smart manufacturing roadmap, the company sought a comprehensive, standardized, and intelligent warehousing solution capable of supporting business growth and lean operations.

Challenges

-

Traditional floor stacking unable to meet high-throughput, high-mix material handling needs

-

Manual operations prone to inefficiencies and errors

-

Lack of digital infrastructure for SKU management, inbound inspection, and route optimization

-

Tight delivery timeline and complex pallet specifications (bulk bags of varying shapes and sizes)

ZIKOO ROBOTICS Solution

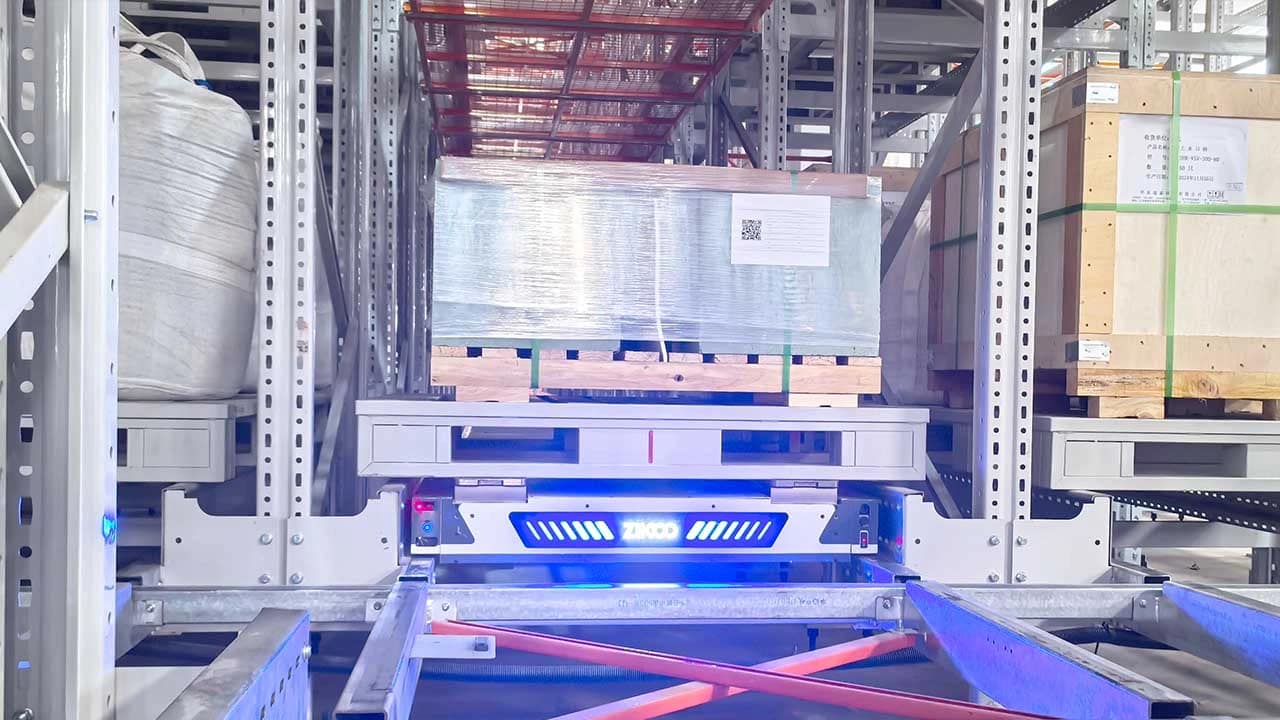

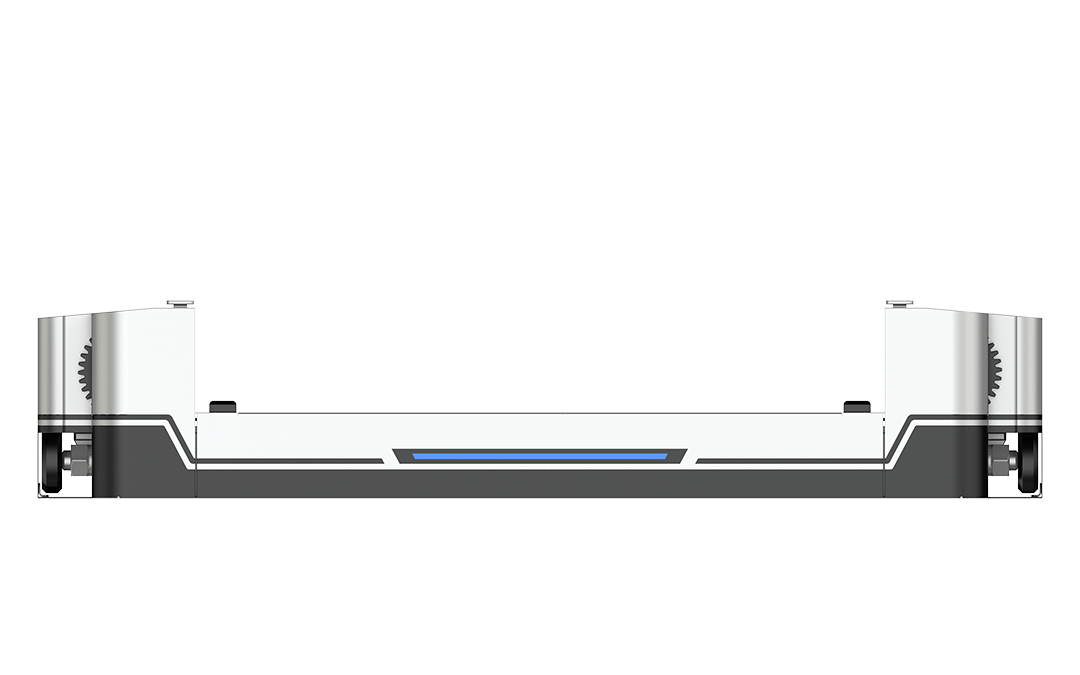

1. Four-Way Shuttle High-Density Storage System

The solution includes three four-way shuttles and two high-speed vertical lifts operating across six-tier racking with over 3,000 storage positions, including 174 custom pallet slots tailored to irregular packaging. Integrated with ZIKOO’s proprietary WMS and WCS platforms, the system delivers intelligent zone management and dynamic slot allocation—enabling high-density, high-efficiency, and high-precision operation.

2. Automated Inbound Quality Check

The system incorporates automated shape and weight verification modules to ensure every pallet meets storage criteria before entering the system.

-

Compliant items → Auto storage

-

Non-compliant items → Rejected with system alert and exception workflow

This ensures accurate inbound records and prepares the system for reliable inventory tracking and dispatch scheduling.

3. Real-Time Warehouse Visualization with Digital Twin

ZIKOO deployed a real-time digital twin engine that mirrors the full 3D warehouse layout and synchronizes with live WMS/WCS data. Capabilities include:

-

Real-time monitoring of equipment status, alerts, and failure points

-

Full traceability of material movement and historical activity logs

-

Predictive maintenance alerts to reduce unplanned downtime

-

Visual dashboards to support data-driven decision-making

4. Rapid Implementation, Scalable Architecture

Built with a modular design, the system was delivered and commissioned in under 80 days. Its scalable architecture allows easy future expansion—whether upgrading shuttle capacity or adding vertical lift modules to support growing SKU complexity or production needs.

System Highlights:

This project demonstrates ZIKOO Robotics’ end-to-end integration capabilities across hardware and software, resulting in a high-performance, high-density, and highly intelligent warehouse system.

At the core is ZIKOO’s proprietary four-way shuttle platform, which seamlessly navigates six-level racking to retrieve and store multiple SKUs of raw materials and finished goods. Working in tandem with high-speed lifts and multi-level shuttle routing, the system enables rapid pallet circulation and supports 24/7 autonomous operation.

To accommodate the irregular dimensions of bulk bags and jumbo sacks common in the building materials sector, the solution integrates precision infrared scanning and dynamic weighing modules for pre-storage validation—ensuring that every load meets operational criteria and enhancing overall storage quality.

The system’s digital twin module offers real-time 3D warehouse replication, enabling proactive monitoring, instant fault response, predictive maintenance, and visualized operation—all contributing to exceptional system reliability and operational transparency.

Combined with WMS/WCS software orchestration, the solution ensures end-to-end digitization and intelligent decision-making. Features such as real-time inventory status, smart slotting, and multi-format SKU handling help eliminate errors from product misplacement and manual tracking.

Delivered in under 80 days, the project achieved a triple breakthrough: ultra-high storage density, high-throughput logistics, and smart, autonomous warehouse management—setting a new benchmark in intelligent warehousing for the building materials industry.

Conclusion:

This case marks a critical step in transforming traditional building materials warehousing into an intelligent, automated, and data-driven operation. By deploying ZIKOO’s “Four-Way Shuttle + Digital Twin” solution, the company has overcome challenges of low density, inefficiency, and disorganized inventory—and laid the foundation for a next-generation smart warehouse built for scalability, precision, and continuous optimization.

ZIKOO Robotics remains committed to empowering industries such as building materials, manufacturing, pharmaceuticals, and energy with tailored, future-ready smart logistics solutions—driving the evolution toward a smarter, greener, and more resilient industrial ecosystem.

Related Products

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-19941778955