High-Density Pallet Shuttle Storage Solution for Fabric Rolls

In the Russian textile industry, fabric roll warehousing has long been constrained by limited warehouse space, high pallet loads, and frequent inbound and outbound operations. Traditional automated storage and retrieval systems (ASRS) often fail to meet real operational needs due to high investment costs, long delivery cycles, and limited system flexibility.

In this project, ZIKOO Robotics deployed a high-density pallet shuttle storage solution centered on Four-Way Shuttle technology, forming a Six-Direction Shuttle System. Within an extremely compact space of only 37 m × 10 m × 3.8 m, the solution enables high-density storage and fully automated handling of fabric rolls.

With a simplified system architecture, fast deployment, and stable operation, the solution significantly reduces overall investment costs and has become a benchmark automated warehousing project for ZIKOO Robotics in the overseas textile industry.

Achievements

Successfully implemented an automated pallet racking system in an extremely limited space

Enabled enterprise-level automated storage at a significantly lower investment cost

Achieved fully automated inbound and outbound handling of fabric rolls

Delivered stable system performance and received high customer recognition

Project Background

In the Russian textile sector, fabric roll storage commonly faces the following challenges:

Limited warehouse space

Large pallet dimensions and concentrated loads

High-frequency inbound and outbound operations

Conventional automated warehouse solutions struggle to balance cost, delivery time, and flexibility, making them unsuitable for such scenarios.

The customer was seeking a cost-effective, fast-to-deploy, and easy-to-maintain automated storage solution capable of delivering dense storage and stable operation within a confined space.

Challenges

1. Limited Warehouse Space

Warehouse dimensions: 37 m × 10 m × 3.8 m

Requirement to achieve Dense Storage under low-clearance conditions

2. Large Pallet Size and High Load

Fabric rolls have uniform dimensions but concentrated weight

High demands on shuttle system stability and positioning accuracy

3. Simplified System Requirement

The customer preferred to avoid complex conveyors and elevators

The system needed to be easy for the local team to learn, operate, and maintain

4. Extremely Tight Delivery Schedule

The project had to be deployed and commissioned within a very short timeframe

ZIKOO ROBOTICS Smart Warehouse Solution

Six-Direction Shuttle Solution Powered by Four-Way Shuttle Technology

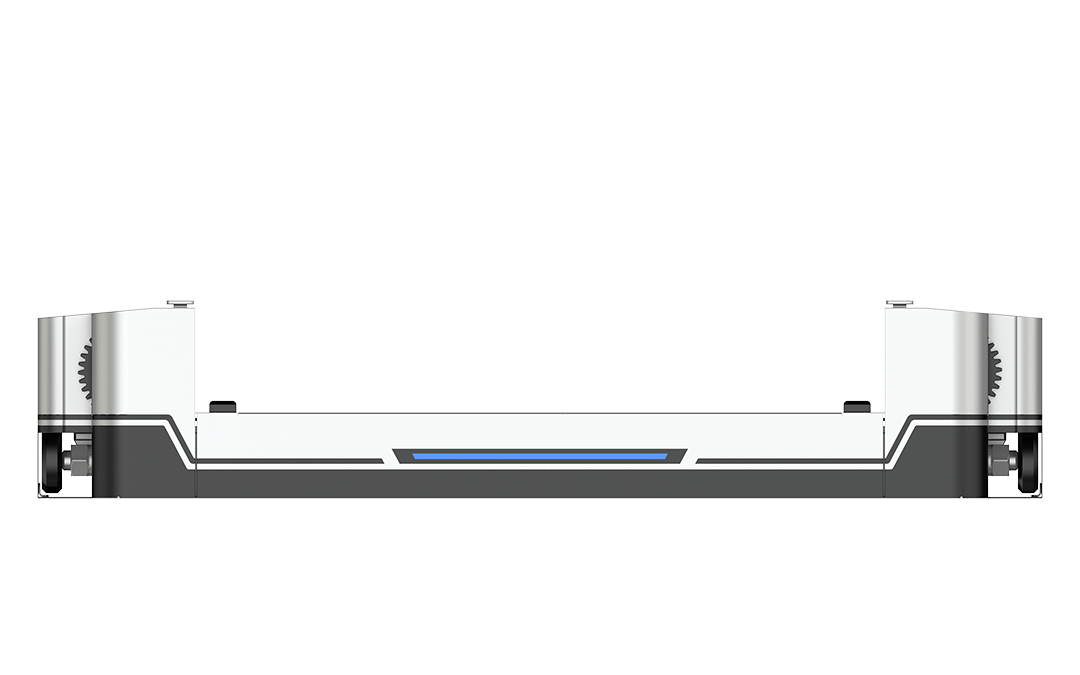

This project adopts the Four-Way Shuttle as the core handling device.

By combining vertical bi-directional transfer units with four-way shuttles, ZIKOO Robotics built a complete Six-Direction Shuttle Solution.

The four-way shuttle performs all critical pallet movements within the racking aisles and serves as the core execution unit of the automated pallet shuttle system.

System Components

Four-Way Shuttle System

Vertical Bi-Directional Transfer Units (for cross-level transportation)

High-density pallet racking system

Workstations directly interfaced with forklifts

WCS (Warehouse Control System) integrated with the customer’s existing WMS

By eliminating traditional elevators and complex conveyor lines, the solution achieves a simpler, more flexible, and more reliable automated storage system.

🔹Maximum Space Utilization

Designed 138 oversized pallet positions (2 m × 1.4 m)

Achieved 95% space utilization

Realized true high-density automated pallet shuttle storage

🔹Standardized Products, Rapid Deployment

Standardized four-way shuttle solution from a professional manufacturer

Ready for operation immediately after installation

Overall project delivery time reduced by 80%

🔹 Simplified System Architecture

No elevators or complex conveyor systems

Workstations directly connected to forklifts

Stable operation, easy maintenance, and fast training for operators

Software & System Integration

WCS (Warehouse Control System) for equipment scheduling

Seamless integration with the customer’s existing WMS

Unified coordination of equipment control, inventory management, and operation commands

This integration demonstrates ZIKOO Robotics’ strong delivery capability as a reliable automated warehousing system supplier.

Project Value

Maximizes warehouse space utilization and unlocks storage potential

Significantly lowers total investment cost compared to traditional ASRS solutions

Shortens project delivery cycles and accelerates system commissioning

Enhances system flexibility to support future business expansion

This project fully demonstrates the core value of a Four-Way Shuttle supplier in high-density storage scenarios.

Conclusion

This Russian textile industry project is a representative overseas success case of a Four-Way Shuttle–based automated storage system by ZIKOO Robotics.

Through a Six-Direction Shuttle Solution centered on Four-Way Shuttle technology, ZIKOO Robotics helped the customer achieve an optimal balance between space utilization, operational efficiency, and investment cost, once again validating its technical strength and global delivery capability as an automated warehousing equipment manufacturer.

ZIKOO Robotics — Global Vision, Local Execution, Empowering Intelligent Warehousing Worldwide.

Related Products

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-19941778955