Building a High-Density, Fast-Response, and Flexible Smart Warehouse – ZIKOO Robotics’ Six-Way Shuttle Powers Four-Star Glass’s Intelligent Upgrade in Pharmaceutical Packaging

As a leading player in the field of pharmaceutical glass packaging, Four-Star Glass has long been at the forefront of intelligent manufacturing. To further advance its digital transformation, the company introduced ZIKOO Robotics’ independently developed Six-Way Shuttle System in its Phase II warehouse project. The goal: to build a high-density, fast-response, and highly scalable smart warehousing solution that aligns with future business growth — setting a new benchmark for intelligent factory operations.

Achievements

- ~60% Increase in Storage Locations, significantly enhancing space utilization.

- 25% Reduction in Installation & Commissioning Time, enabling faster go-live.

- Marked Improvement in Warehouse Efficiency, ensuring faster order fulfillment.

- 10% Decrease in Overall Investment Cost, delivering cost-effective performance.

Project Background

Recognized as a “National Little Giant Enterprise” and “Manufacturing Single Champion”, Four-Star Glass focuses on the R&D and production of neutral borosilicate glass — a core material in pharmaceutical packaging. In its journey toward building a smart factory, warehousing plays a pivotal role in driving production efficiency and overall operational performance.

While the Phase I warehouse successfully leveraged a four-way shuttle system to initiate automation, Phase II brought new challenges: increased SKUs, frequent batch changes, and heightened demands for fine-grained inventory control. To address these needs, Four-Star Glass once again partnered with ZIKOO Robotics to deploy the next-generation Six-Way Shuttle System, advancing toward a more intelligent, dynamic storage model.

Challenges

- Insufficient Storage Density: Traditional elevators and racking structures led to wasted vertical space.

- Slow Response Times: Complex equipment integration hindered coordination between storage and production lines.

- High Investment Costs: Chain conveyors and electrical control systems required costly maintenance.

- Lack of Flexibility: Inability to adapt to future increases in SKUs or throughput.

ZIKOO ROBOTICS Solution

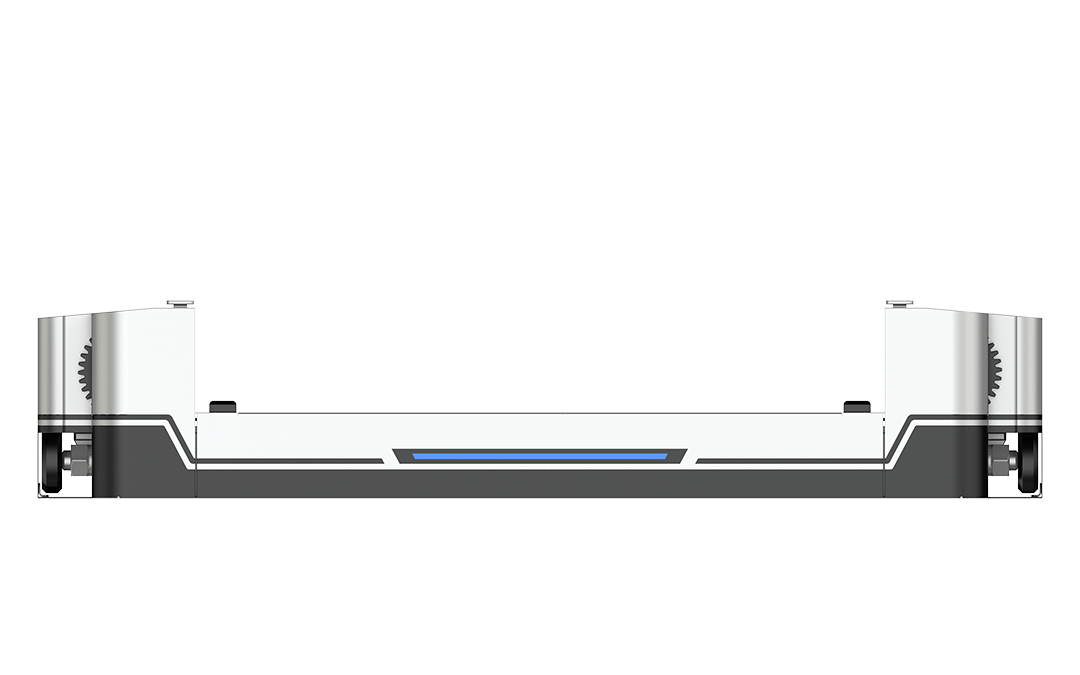

1. Six-Way Shuttle for High-Density Automated Picking

The system integrates six-way shuttles, PTP warehouse management software, and multifunctional workstations. Combining horizontal and vertical movement with cross-layer access, the shuttle can reach any position within the racking structure, significantly increasing storage density and accessibility.

2. Multifunctional Workstations Replace Traditional Conveyance

Each workstation integrates barcode scanning, pallet guidance, shape inspection, and control functions, replacing traditional chain conveyors and connecting lines. This modular setup greatly simplifies installation and reduces maintenance, enabling standardized, plug-and-play deployment.

3. Space Saving, Efficiency Boosting

The use of vertical two-way shuttles in place of traditional elevators reduces space consumption — occupying only a single pallet position. The overall number of storage positions is increased by around 60%, while multi-shuttle coordination enables high-frequency picking at single points, boosting operational efficiency.

4. Shorter Deployment Cycle

As a modular, standardized product, the Six-Way Shuttle requires minimal onsite electrical configuration. Installation and commissioning are rapid, with project deployment time reduced by 25% compared to traditional systems — supporting fast-track implementation.

5. Highly Scalable Architecture

The system is designed for flexible expansion, allowing for easy addition of shuttles and storage locations in response to SKU growth or business needs. This ensures a future-ready solution with strong return on investment.

Seamless Integration and System Highlights:

-

The raw materials warehouse features two multifunctional workstations, one of which connects directly to a second-floor production line — enabling seamless warehouse-to-line operations.

-

The system supports automated “goods-to-person” picking, driven by ERP or WMS scheduling with minimal manual intervention. This improves both labor efficiency and picking accuracy.

-

Features such as inventory alerts, dynamic stock allocation, and visualized warehouse mapping enable comprehensive monitoring, traceability, and ongoing optimization.

Conclusion:

Through this collaboration, ZIKOO Robotics’ Six-Way Shuttle System has enabled Four-Star Glass to build a future-oriented intelligent warehouse tailored for pharmaceutical packaging — once again validating the system’s superior fit for high-density, high-frequency, and precision storage scenarios.

Looking ahead, ZIKOO Robotics will continue to drive innovation and deployment of the Six-Way Shuttle across industrial manufacturing, pharmaceuticals, 3PL logistics, and more — helping global enterprises realize their smart logistics ambitions and set new industry standards.

Related Products

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-19941778955