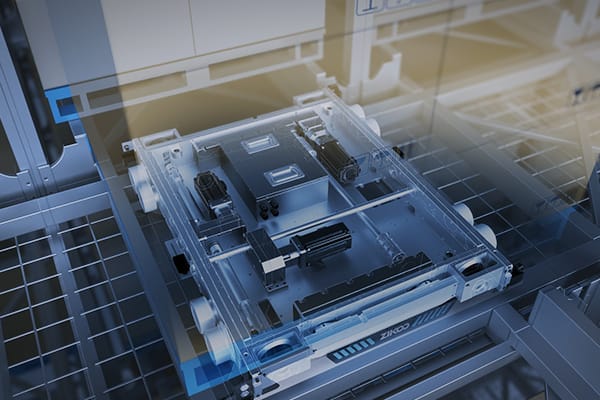

Warehouse automation keeps evolving, and four-way shuttle systems have become a practical answer to the storage and throughput challenges many facilities face today. The R-bot Four-Way Shuttle from Zikoo Smart Technology brings together dense storage capability, flexible movement, and software integration in ways that make real differences for operations dealing with space constraints and labor pressures.

Getting More Storage From the Same Footprint

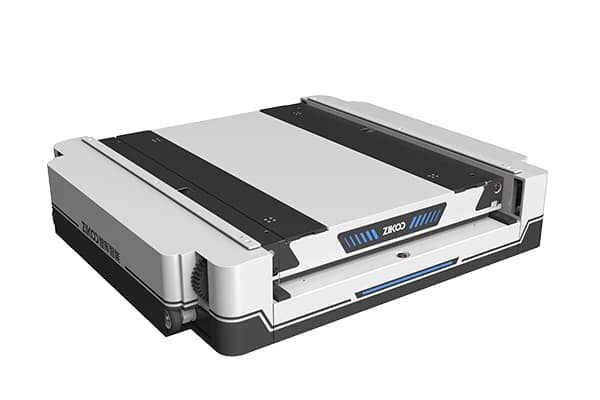

The math on warehouse space is simple but unforgiving. Every square meter costs money, and wasted vertical or horizontal space directly hits the bottom line. The R-bot addresses this with a body thickness of just 125 mm and load capacity reaching 1.5 tons, allowing storage configurations that go deeper and higher than conventional setups permit.

What this means in practice: narrower aisles, more rack positions, and better use of ceiling height. Multiple shuttles can work the same storage zone simultaneously, turning layouts that once seemed fixed into genuinely dense environments. E-commerce fulfillment centers and distribution hubs see particular benefit here, where every pallet position matters.

The system also handles specialized conditions. Cold chain operations running at -25℃ get dedicated low-temperature lithium batteries, and pharmaceutical facilities requiring constant temperature control can deploy the same platform with appropriate modifications.

| Feature | Manual Storage | Four-Way Shuttle System |

|---|---|---|

| Storage Density | Low | High |

| Aisle Space | High | Low |

| Vertical Utilization | Limited | Excellent |

| Pallet Access | Manual/Forklift | Automated |

Moving Goods Faster Through the Building

Speed in material handling translates directly to throughput numbers and order fulfillment rates. The R-bot’s four-way movement capability means it can navigate storage racks without the repositioning delays that limit single-direction systems.

Pairing the R-bot with H-bot High-Speed Elevators creates what amounts to a six-way shuttle system, handling vertical and horizontal transport as a unified network. The H-bot Vertical Bidirectional Shuttle delivers ±1 mm positioning accuracy at loaded speeds of 0.5 m/s, functioning as the vertical hub that moves pallets between levels without bottlenecks.

This combination supports goods-to-person fulfillment strategies where picking stations receive pallets automatically rather than workers traveling to inventory locations.

What Makes Four-Way Shuttle Systems Worth Considering

The flexibility advantage shows up in several ways. Moving pallets in all four directions within rack structures means more inventory positions remain accessible without traffic conflicts. Dynamic storage strategies become possible, where the system places and retrieves goods based on demand patterns rather than fixed locations.

Scalability matters too. These systems grow incrementally. Adding shuttles or expanding rack zones doesn’t require rebuilding the whole installation. Throughput increases come from adding units rather than replacing infrastructure.

Adapting to Changing Business Requirements

Warehouse needs shift. Seasonal peaks, product mix changes, and business growth all create pressure on storage and handling capacity. The R-bot’s modular architecture means expansion happens in stages rather than through wholesale replacement.

The PTP Smart Warehouse Software suite handles coordination across the system. WMS, WES, WCS, and RCS components work together to manage task allocation, optimize routing, and maintain real-time inventory visibility. When operational strategies need adjustment, software configuration changes rather than hardware modifications often provide the solution.

Pallet compatibility extends across common formats including American (1016 × 1219 mm) and Japanese (1100 × 1100 mm) sizes, reducing constraints when working with diverse product flows or international supply chains.

For operations exploring advanced warehouse automation approaches, 《Six-Way Shuttle: Pioneering the Future of Smart Warehousing》 covers related developments in this space.

Cutting Costs and Reducing Labor Dependency

Automation economics work on multiple fronts simultaneously. Labor costs drop as fewer workers handle routine material movement. Error rates decline because automated systems follow programmed paths consistently. Product damage decreases when human handling steps get removed from the process.

Safety improvements matter beyond the obvious humanitarian concerns. Fewer workers in active storage zones means fewer injury incidents, lower insurance costs, and reduced operational disruptions from accidents.

The U-bot Omnidirectional Stacker Robots complement R-bot deployments by handling narrow aisle storage with minimum aisle widths of 2100 mm and lifting heights reaching 8 meters. This combination allows facilities to automate high-density zones that would otherwise require specialized equipment or manual handling.

Workers freed from repetitive material movement can shift to activities where human judgment adds value. Quality control, exception handling, and customer service often benefit from this reallocation.

| Cost Factor | Manual Operations | Automated Shuttle System |

|---|---|---|

| Labor Costs | High | Low |

| Error Rates | Moderate to High | Low |

| Safety Incidents | Higher | Significantly Lower |

| Space Utilization | Lower | Higher |

| Throughput Capacity | Limited | High |

Understanding the Financial Returns

ROI calculations for four-way shuttle implementations typically show favorable numbers across several categories. Labor savings provide the most visible returns, but increased throughput contributes to revenue capacity that often exceeds initial projections.

Space utilization improvements can delay or eliminate warehouse expansion projects, avoiding capital expenditure that would otherwise be unavoidable. Faster order fulfillment supports customer satisfaction metrics that influence retention and growth.

The combined effect usually produces payback periods that make the investment attractive for operations with sufficient volume to justify automation.

Working With What You Already Have

Brownfield installations present different challenges than greenfield builds, but the R-bot system handles both scenarios. Compatibility with various racking configurations means existing structures often accommodate the new equipment without major modifications.

The PTP Smart Warehouse Software provides the integration layer that connects automated equipment with existing business systems. API capabilities allow data exchange with established WMS and ERP platforms, maintaining continuity in how the business tracks inventory and processes orders.

Real-time communication between software components and physical equipment keeps operations synchronized. Task allocation responds to current conditions rather than following rigid schedules, and resource management adjusts as situations change throughout the day.

Making Integration Work in Practice

Software connectivity handles most of the integration complexity. Existing warehouse management systems continue functioning while the automation layer takes over physical execution. This approach preserves investments in current IT infrastructure while adding new capabilities.

Physical installation adapts to site conditions. The modular design means components fit within various racking structures, and facilities can often retrofit current warehouses with limited structural changes. Older buildings that might seem unsuitable for automation frequently prove workable with appropriate planning.

For detailed information on software integration approaches, 《PTP Intelligent Warehouse Software Empowers Enterprises for Smart Upgrades》 provides additional context.

Building Capacity for What Comes Next

Supply chain complexity keeps increasing. Customer expectations for delivery speed continue rising. Labor availability remains uncertain in many markets. These trends suggest that warehouse operations will face ongoing pressure to do more with less.

The R-bot platform, combined with H-bot elevators and U-bot stackers, creates an automated ecosystem that can respond to changing conditions. Scaling up means adding units. Adjusting to new product mixes means reconfiguring software. Handling volume fluctuations means deploying equipment where current demand requires it.

This adaptability provides a hedge against uncertainty. Operations that can adjust quickly to market shifts maintain competitive position better than those locked into fixed configurations.

Working With Zikoo Smart Technology

Zikoo Smart Technology Co., Ltd. develops pallet-to-person robotics solutions including the R-bot Four-Way Shuttle, U-bot Omnidirectional Stacker Robots, and H-bot High-Speed Elevators, integrated through PTP Smart Warehouse Software. For information about how these systems might apply to specific operational requirements, contact [email protected] or call (+86)-19941778955.

Common Questions About Four-Way Shuttle Systems

How Do Four-Way Shuttles Compare to Traditional ASRS

Traditional automated storage and retrieval systems typically use fixed-path cranes or shuttles with limited directional movement. Four-way shuttles like the R-bot move both horizontally and perpendicularly within storage aisles, providing access flexibility that fixed-path systems cannot match. This multidirectional capability supports more dynamic storage strategies and reduces the bottlenecks that occur when multiple retrieval requests compete for the same aisle.

Which Operations Benefit Most From This Technology

High-density storage requirements and rapid order fulfillment needs point toward four-way shuttle suitability. E-commerce warehouses managing diverse SKUs with quick turnaround demands see strong results. Cold storage facilities and pharmaceutical operations benefit from the R-bot’s specialized battery options and environmental adaptability. Distribution centers handling high volumes with space constraints often find the technology addresses their primary operational challenges.

What About Existing Facilities That Weren’t Designed for Automation

Brownfield installations work with appropriate planning. The R-bot’s modular design accommodates various racking configurations, and the PTP software suite integrates with existing IT systems. Many facilities that appear unsuitable for automation prove workable once the specific site conditions get evaluated. Retrofit projects typically proceed with less disruption than complete warehouse rebuilds would require.