Modern warehouses ask a lot of their storage systems, and the stakes around picking the right automation are real. Get it right and throughput, space utilization, and labor planning fall into place. Here, we focus on four-way shuttle technology within automated storage and retrieval systems, covering how it works, who’s leading the field, the performance measures that matter, integration with core software platforms, and the trends likely to shape what comes next.

Understanding Four-Way Shuttle Systems in Logistics

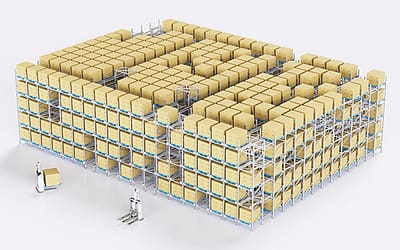

Four-way shuttle technology marks a major step forward in automated storage and retrieval systems (ASRS). These robots move on multiple axes, traveling horizontally within aisles and shifting perpendicularly between them. That omnidirectional motion supports flexible layouts and dense storage. In practice, shuttles retrieve and deposit pallets or containers from designated locations, then run goods to a pick-and-place station or elsewhere in the warehouse. It’s a direct path to higher intralogistics efficiency.

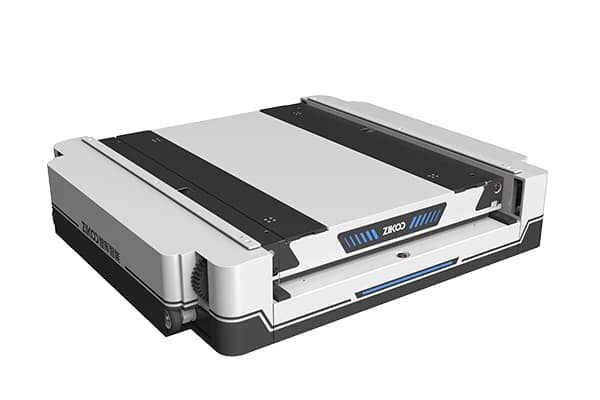

The R-bot Four-way Shuttle is built for dense storage and pallet-to-person workflows. Its slim 125 mm body carries up to 1.5 tons. Four-way movement enables intelligent autonomous handling and smooth multi-shuttle collaboration. Paired with the H-bot Vertical Bidirectional Shuttle, it becomes a six-way shuttle system that fits a wide range of palletized storage and picking tasks. Typical deployments include e-commerce warehouses, distribution centers, and specialized sites such as cold chain food and pharmaceutical constant temperature facilities.

Key Brands Driving Four-Way Shuttle Innovation

Automated material handling is a fast-moving market, and several shuttle makers keep pushing the envelope. Each brings strengths in mechanical design, software, and application depth. Zikoo Smart Technology offers the R-bot Four-way Shuttle in multiple variants, including the Standard Type (R1200B), American Type (R1200A), Japanese Type (R1500J), and Heavy-duty Type (R1500B, R2000B). These cover pallet sizes and loads from 1200 kg to 2000 kg. Empty speed reaches up to 1.6 m/s, with loaded speed up to 1.2 m/s. All models run on lithium batteries for 7–8 hours of continuous operation, even at -15℃.

We also develop specialized solutions. The Cold Chain Custom Solution for the R-bot features -25℃ low-temperature dedicated lithium batteries and specialized PCBA coating for high humidity. For new energy applications, our custom configuration avoids copper, zinc, nickel, and lead, using stainless steel frames and all-rubber buffer wheels to prevent contamination. These options reflect the breadth of capabilities available from leading providers.

For more information on selecting the right partner, consider reading 《Looking for Reliable Four-Way Shuttle Manufacturers? Choose Zikoo Robotics》.

Evaluating Shuttle System Performance and Scalability

Evaluating a four-way shuttle system comes down to a few core indicators. Throughput, measured in pallets per hour, sets the pace. Storage capacity, or pallets per square meter, shows how well space is being used. Energy efficiency relates to battery life and charging cycles, shaping operating costs. Scalability matters too; the system should grow cleanly as demand increases.

| Feature | Zikoo R-bot (Standard) | Zikoo R-bot (Heavy-duty) |

|---|---|---|

| Rated Load | 1200 kg | 1500-2000 kg |

| Empty Speed | 1.6 m/s | 1.35 m/s |

| Loaded Speed | 1.2 m/s | 1.0 m/s |

| Body Thickness | 125 mm | 125-150 mm |

| Continuous Operation | 8 hours | 7 hours |

| Min. Temperature | -15℃ | -15℃ |

Our R-bot models are tuned for consistent output. The R1200B carries a rated 1200 kg with an empty speed of 1.6 m/s. The R2000B, a heavy-duty large pallet type, handles 2000 kg. Together, these figures illustrate how capacity and speed scale across the range.

Seamless Integration with Warehouse Management Systems

Automated warehouse performance depends on clean connections with existing software. Warehouse Management Systems (WMS), Warehouse Execution Systems (WES), and Warehouse Control Systems (WCS) govern data flow, coordinate robot movement, and protect inventory accuracy.

Zikoo’s PTP Smart Warehouse Software (WMS/WES/WCS/RCS) provides unified control and efficiency. The platform directs our R-bot Four-way Shuttle and H-bot High-Speed Elevators for synchronized operations. It manages tasks from inbound receiving through outbound shipping, refining routes and cutting idle time. Solid software integration is what turns automation into measurable returns.

Future Trends in Automated Shuttle Storage

Warehouse automation is advancing quickly on the strength of AI and robotics. Expect deeper use of artificial intelligence for predictive maintenance and better task scheduling. Robotics will continue to advance in navigation and collaboration. Sustainability will matter more, with energy-efficient designs and recyclable components gaining ground. Systems such as the six-way shuttle, combining the R-bot Four-way Shuttle with the H-bot Vertical Bidirectional Shuttle, point the way. That pairing creates a three-dimensional transportation network, lifting throughput and efficiency.

Elevate Your Warehouse Operations

Zikoo Smart Technology offers cutting-edge solutions to improve your warehouse. Our U-bot Omnidirectional Stacker Robots, R-bot Four-Way Shuttle, and H-bot High-Speed Elevators drive strong efficiency. Our PTP Smart Warehouse Software (WMS/WES/WCS/RCS) delivers coordinated control and optimization. Contact us today at [email protected] or (+86)-19941778955 to discuss a tailored automation solution for your facility.

Frequently Asked Questions

How do four-way shuttle systems optimize warehouse space?

Four-way shuttle systems increase storage density by supporting narrow aisles and multi-deep configurations. With omnidirectional movement, racks can be laid out more flexibly, and vertical space can be used more fully. The result is a clear lift in storage capacity compared with traditional approaches, which fits well with automated warehouse strategies.

What are the key benefits of implementing automated shuttle technology?

Automated shuttle technology reduces labor costs, increases throughput and order speed, improves inventory accuracy, enhances safety, and adds operational flexibility. It sits at the heart of advanced automated material handling, providing efficiency and room to scale.

How do different shuttle brands compare in terms of scalability and integration?

Shuttle brands differ in how they scale and connect with existing systems. Leading providers offer modular designs that expand as volumes grow, supporting both horizontal and vertical scaling. Integration with Warehouse Management Systems (WMS) and other automation is central, with some vendors offering proprietary suites such as PTP Smart Warehouse Software to keep operations coordinated.