Smart Pharma Warehousing Upgrade: Safeguarding Every Dose with Intelligence

The safety and traceability of pharmaceutical storage and distribution are directly tied to public health. In alignment with national strategies promoting “Smart Healthcare” and “Intelligent Manufacturing,” the pharmaceutical industry is accelerating the shift toward automation and digitalization in warehousing.

As a leading Four-Way Shuttle Manufacturer and automated warehouse integrator, ZIKOO Robotics partnered with Chongqing Genrix Biopharmaceutical Co., Ltd. (hereinafter referred to as “Genrix Bio”) to build a highly standardized, automated dense storage solution based on the Four-Way Shuttle System and Automated Storage and Retrieval System (AS/RS). Designed to fully comply with GMP/GSP regulations, the project establishes a benchmark for smart logistics in the pharmaceutical sector by boosting efficiency and ensuring strict drug safety.

Achievements

Since going live, the smart warehouse solution has delivered remarkable results in operational efficiency, space utilization, and system intelligence:

- Over 3× Increase in Storage Density: Optimized spatial layout enabled high-density vertical storage.

- Faster Operational Response: Four-way shuttle robots ensure synchronized, high-speed handling aligned with production rhythms.

- Digital Management Upgrade: A digital twin system enables real-time equipment and inventory visualization, improving decision-making.

- Modular & Scalable Architecture: The system is designed for future expansion as business requirements evolve.

Project Background

Limitations of Traditional Pharmaceutical Warehousing

- Strict Environmental Requirements, Poor Compliance:

Biopharmaceuticals require precise temperature (2°C–8°C) and humidity (35%–75%) control with protection against light, fire, and moisture. Manual warehouses struggle to maintain such conditions consistently, risking product integrity. - Complex Order Structures, Inefficient Picking:

With a wide variety of SKUs, frequent batch changes, and diversified order formats, traditional warehouses relying on manual handling and paper processes are slow and error-prone. - Fragmented Systems, Limited Visibility:

Lack of centralized tracking systems leads to information silos and fails to meet the full traceability and compliance demands of GMP/GSP standards.

Challenges

Before the upgrade, Genrix Bio faced the following core warehousing issues:

- Low Storage Density: Floor stacking led to significant vertical space waste, limiting capacity expansion.

- Manual Operations, Slow Throughput: Inefficient material handling and unclear picking paths restricted overall output.

- High Dependency on Manual Labor: Frequent data delays and inventory errors hindered accurate management.

- Lack of Flexibility: The previous system could not accommodate SKU growth or layout adjustments tied to production changes.

ZIKOO ROBOTICS Smart Warehouse Solution

Powered by Dense Storage & Smart Logistics

- High-Density, Multi-Level Storage: 6× Capacity Gain

ZIKOO built a three-level Automated 3D Warehouse occupying only 480㎡, yet accommodating 645 pallet positions. Equipped with 2 Four-Way Shuttles, 2 high speed elevators, and a modular conveyor system, the solution delivers significant gains in storage efficiency under a compact footprint.

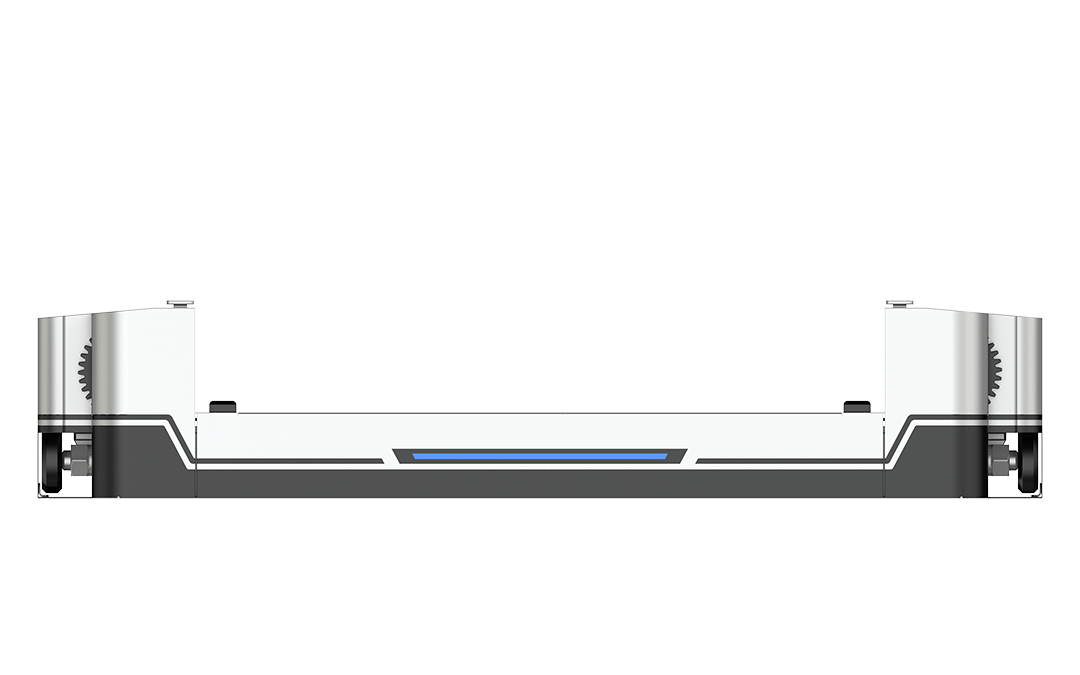

- Four-Way Shuttle System: Enabling “Goods-to-Person” Picking

The Four-Way Shuttles traverse both longitudinal and lateral directions and coordinate with lifts for multi-level transport. Supporting full-pallet retrieval, dynamic batch picking, and return-to-rack workflows, this AS/RS system automates picking while dramatically improving speed and accuracy.

- Intelligent Control Core: Unified & Real-Time Operations

Through seamless integration of WCS and RCS with Genrix Bio’s existing WMS, the system ensures synchronized operations, inventory tracking, and device coordination. It enables real-time visibility and control over the entire inbound-to-outbound flow.

- Enclosed, Climate-Controlled Storage: Full GMP/GSP Compliance

The warehouse features a sealed structure with precise temperature and humidity control systems, meeting strict pharmaceutical storage standards for cold chain logistics (2–8°C) and protecting against light, moisture, and fire hazards.

Solution Highlights

✅ Dense Storage Architecture: 6× increase in storage capacity per unit area, reducing land and construction costs

✅ Fully Automated Picking: End-to-end automation with >99.9% picking accuracy and no manual transport

✅ Real-Time Data Control: Integrated WMS, WCS, RCS platform for traceable, transparent warehouse operations

✅ GMP-Compliant Storage Conditions: Full environmental controls with closed-loop safety measures

✅ Modular & Scalable: Rapid deployment, flexible expansion, and seamless adaptation to business change

Project Value: Enabling High-Quality Growth in Pharma Supply Chains

🔹 Improved Operational Efficiency: Automated palletizing, picking, and dispatch significantly reduce cycle times

🔹 Reduced Risk of Human Error: Intelligent monitoring and error-proofing mechanisms improve process reliability

🔹 Regulatory Compliance: End-to-end traceability and real-time records to support full GMP/GSP lifecycle audits

🔹 Optimized Use of Space & Energy: Vertical dense storage maximizes cubic space and reduces energy overhead

🔹 Accelerated Digital Transformation: A holistic solution combining hardware, software, and operational strategy to reshape pharma warehousing infrastructure

Customer Testimonial

“This smart warehouse marks a major step forward in our ability to manage pharmaceutical logistics. With ZIKOO’s support, we’ve not only improved operational efficiency but also strengthened the reliability of drug quality control—successfully transforming from traditional management to intelligent warehousing.”

— Logistics Director, Genrix Biopharmaceutical

ZIKOO Robotics: Trusted Four-Way Shuttle Supplier & AS/RS Integrator

As a leading Four-Way Shuttle Supplier and dense storage system provider, ZIKOO Robotics is committed to innovating intelligent warehouse solutions tailored to the pharmaceutical industry. We continue to drive the standardization and industrialization of Automated 3D Warehousing and AS/RS technologies, empowering enterprises to build a secure, efficient, and future-ready pharmaceutical supply chain.

Want to explore smart warehousing for your pharmaceutical operations?

👉 [Contact ZIKOO Robotics] for custom consultations and project planning.

Related Products

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-19941778955