Smart Storage for Smart Textiles

— 4-Way Pallet Shuttle Powers Warehouse Efficiency in the Textile Industry

To meet the fast-paced demands of new retail models — including quick response, small-batch production, and high-frequency orders — ZIKOO ROBOTICS partnered with a well-known textile enterprise to build a smart dense storage system.

By deploying the 4-way pallet shuttle as the core equipment, the project enabled a full upgrade from basic “pile-and-store” to intelligent “store-and-pick” warehousing.The system successfully handled over 4,000 SKUs with frequent inbound and outbound operations, setting a new benchmark for intelligent warehousing in the textile industry.

Achievements

- Storage Efficiency Doubled: Maximized storage capacity within the original footprint, significantly improving space utilization.

- Picking Efficiency Increased by 60%: Multi-access picking ports + WCS intelligent scheduling reduced repetitive movement.

- Labor Reduced by 50%: Post-deployment, picking staff reduced from 6 to 3.

- Faster Response: Dynamic task allocation ensured stable performance during peak demand.

- Scalable System: Supports future expansion of shuttles and lifting units as needed.

Project Background

As SKU counts grow and lead times shrink, textile companies are facing three core warehousing bottlenecks:

- Low Storage Density: Traditional shelving and manual stacking can’t meet textile-specific needs.

- Low Picking Efficiency: Manual searching and long travel paths increase error rates.

- Poor Operational Flexibility: Frequent order changes exceed traditional system responsiveness.

The customer aimed to resolve the warehouse-to-production coordination gap and boost overall supply chain efficiency through warehouse automation.

Challenges

- High SKU Complexity: Over 4,000 textile SKUs with frequent inbound/outbound activity.

- Irregular Storage Units: Rolled fabrics vary in size and volume.

- Space Constraints: Warehouse net height only 6 meters — how to achieve dense vertical storage?

- Flexible Picking Requirements: Customer needed real-time, multi-SKU, on-demand picking capabilities.

ZIKOO ROBOTICS Smart Warehouse Solution

Facility Overview

- Warehouse Area: 1,566 m² | Net Height: 6 m

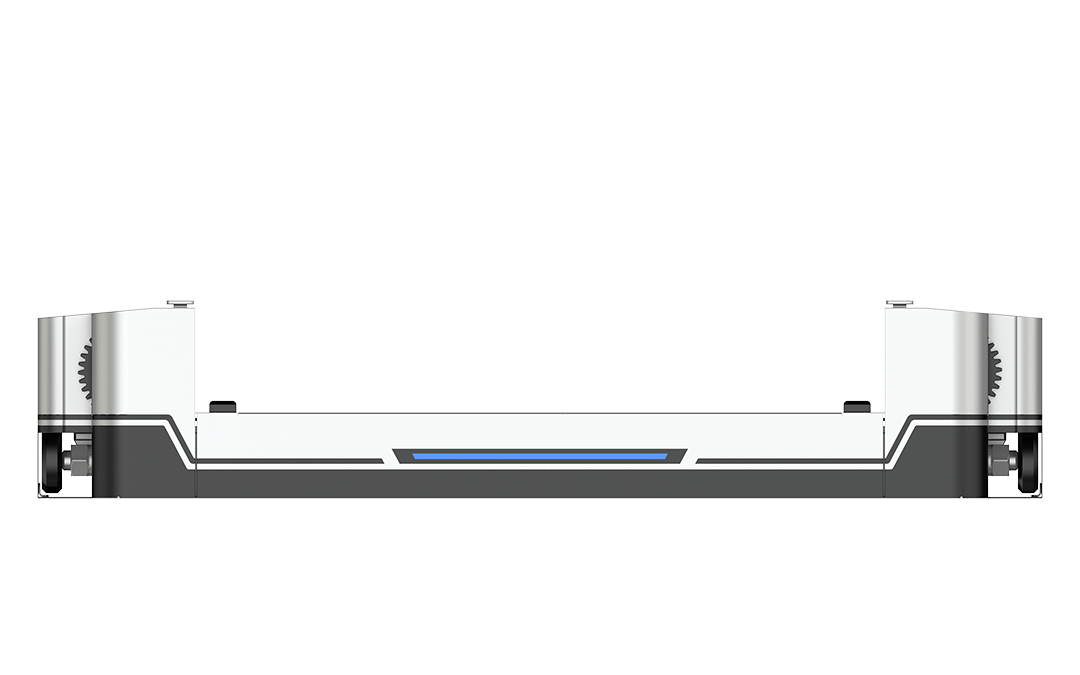

- Equipment: 4 × 4-Way Pallet Shuttles, 2 × Lifts, 1 × WCS System

- Inbound/Outbound Ports: 3 (each with PDA + display screen)

- Custom Totes: Two height options with 3-sided enclosures + open front, adapted for rolled textiles

Solution Highlights

- Flexible Scheduling System

WCS dynamically allocates task routes; lifts are no longer bound to fixed ports, maximizing equipment utilization. - Pick-on-Demand

In/out ports double as picking stations, eliminating transfers and improving efficiency — ideal for fast-moving orders. - High-Density Layout

4-way pallet shuttles break traditional aisle limitations, enabling multi-lane access and optimal space usage. - Smart Warehouse-to-Production Integration

Picked fabric is delivered directly to the second-floor workshop — achieving full-process connectivity and fast production response.

The project is managed under ZIKOO’s PTP Warehouse Control System, integrating software and hardware to dynamically adapt device strategies to business demand.

The system interfaces seamlessly with the enterprise’s WMS/ERP, delivering end-to-end data visibility and process closure — from receiving and picking to inventory and outbound.

With reserved hardware expansion points and flexible logic interfaces, the platform supports scalable shuttle quantity, conveyor system integration, and third-party system docking — offering a truly flexible and evolvable smart warehouse platform.

Client Feedback

Post-deployment, the customer reported:

- Smooth shuttle operation, fast scheduling response, and user-friendly system

- Picking efficiency for high-frequency SKUs increased by over 2×

- Warehouse staff reduced by nearly half, with a sharp increase in productivity

The solution has since been adopted as the template for national warehouse network replication, laying a solid foundation for the customer’s textile supply chain digital transformation.

Conclusion:

This project not only solved challenges in space utilization, picking efficiency, and labor cost, but also leveraged the standardization and flexibility of 4-way pallet shuttle technology to fulfill the textile industry’s pursuit of high-efficiency, flexible, and intelligent warehousing.

ZIKOO ROBOTICS — a leading innovator in pallet shuttle robotics, continues to deliver flexible, efficient, and intelligent smart warehouse solutions across industries.

Related Products

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-19941778955