Selecting the optimal warehouse storage system shapes day-to-day efficiency and long-term cost. We continuously test technologies that improve material flow and squeeze more from the same footprint. This comparison looks at pallet shuttle systems and traditional racking, their operational impacts, and where each fits across different warehouse environments. The intent is to offer clear, usable insight for teams planning a storage upgrade.

Understanding the Fundamentals: Defining Pallet Shuttle and Traditional Racking Systems for Modern Warehouses

Modern warehouses need storage that can flex with shifting product mixes. We group systems by how they operate and the types of goods they suit. Knowing these differences helps tune a facility for better performance.

1. What is a Pallet Shuttle System and How Does it Revolutionize Dense Storage?

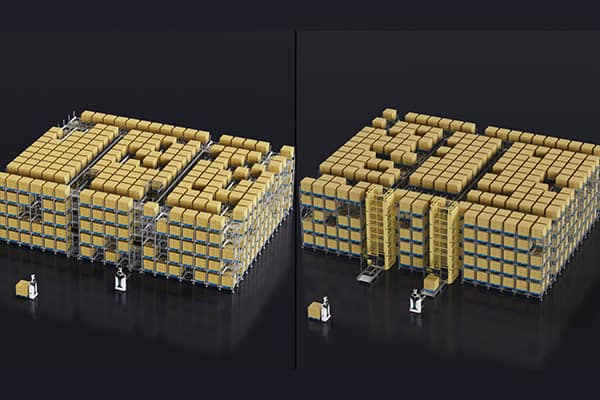

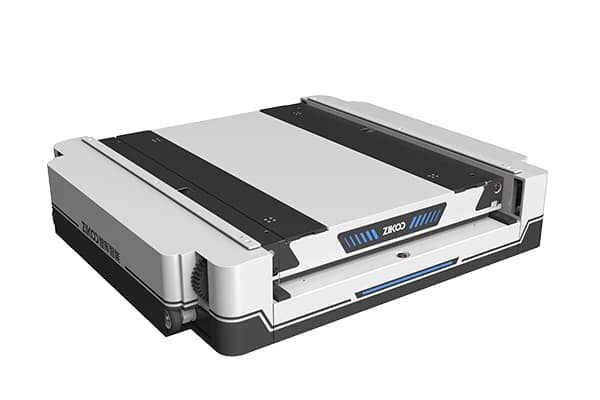

A pallet shuttle system uses automated carts, such as our R-bot Four-way Shuttle, to move pallets inside racking lanes. By minimizing aisle space, this approach enables highly Dense storage. The R-bot’s slim 125mm body and 1.5-ton capacity allow flexible four-way movement and multi-shuttle collaboration. When integrated with the H-bot Vertical Bidirectional Shuttle, it forms a Six-way shuttle system, significantly boosting throughput. This approach revolutionizes high-density storage scenarios.

2. Exploring Traditional Racking: The Enduring Foundation of Warehouse Storage

Traditional racking systems, including selective or drive-in racks, store pallets in fixed locations with direct access to every position. They require wider aisles for forklifts, which reduces storage density. Their simplicity and lower initial cost keep them foundational for many warehouses.

A Head-to-Head Comparison: Key Criteria for Evaluating Pallet Shuttle and Traditional Racking Performance

The decision comes down to a few performance levers. We evaluate space utilization, throughput, and cost to guide our clients. Each criterion ties directly to operational efficiency and profitability.

1. Space Utilization: Maximizing Storage Density in Your Warehouse Footprint

Pallet shuttle systems raise storage density well beyond traditional racking. By eliminating extensive forklift aisles, these systems can utilize up to 85% of available warehouse space. For example, our R-bot Four-way Shuttle enables dense storage in e-commerce warehouses and cold chain facilities. Traditional racking remains versatile but typically achieves lower density due to aisle requirements.

2. Throughput and Efficiency: Accelerating Operations and Reducing Labor Dependence

Automation in pallet shuttle systems drives higher throughput and smoother operations. The R-bot Four-way Shuttle moves at up to 1.6 m/s empty and 1.2 m/s loaded, automating pallet handling. This reduces manual labor and speeds picking. Traditional racking relies on forklifts, which can slow throughput and raise labor costs.

3. Initial Investment and Long-Term Operational Costs: A Comprehensive Financial Analysis

A pallet shuttle system generally requires a higher initial investment than traditional racking. Over time, savings come from reduced labor, optimized space, and lower energy consumption. For instance, our R-bot operates for 7-8 hours on a single charge. Traditional racking has lower upfront costs but higher ongoing expenses due to labor and less efficient space use.

| Feature | Pallet Shuttle System (e.g., Zikoo R-bot) | Traditional Racking (e.g., Selective Racking) |

|---|---|---|

| Storage Density | High (up to 85% space utilization) | Moderate to Low (requires wider aisles) |

| Throughput | High (automated, fast pallet movement) | Moderate (manual forklift operation) |

| Labor Dependence | Low (automated handling, pallet-to-person) | High (manual forklift operation) |

| Initial Investment | Higher | Lower |

| Operational Costs | Lower (reduced labor, energy) | Higher (labor-intensive, less efficient space) |

| Flexibility | High (adaptable to various pallet sizes, four-way movement) | Moderate (limited by rack configuration) |

| Scalability | High (easy to expand with additional shuttles) | Moderate (requires additional racking structures) |

| Application | Dense storage, cold chain, e-commerce, manufacturing | General storage, diverse SKUs, lower volume |

| Temperature Range | Down to -25℃ (with specialized batteries) | Standard warehouse temperatures |

| Pallet Handling | Automatic, intelligent autonomous handling | Manual, forklift-dependent |

| Integration | Seamless with WMS/WES/WCS/RCS for Six-way shuttle system functionality | Basic integration with WMS for location tracking |

| Body Thickness | As slim as 125 mm | N/A |

| Load Capacity | Up to 2000 kg | Typically up to 1000 kg per pallet position (varies by design) |

Advanced Features and Application Scenarios: Where Each System Excels and How Zikoo Enhances Automation

We engineer solutions around specific industry challenges. Our pallet shuttle systems provide features traditional racking can’t match, enabling stronger performance in demanding environments.

1. Automation and Integration Capabilities: Seamlessly Connecting with WMS and Robotics

Our pallet shuttle systems integrate directly with PTP Smart Warehouse Software (WMS/WES/WCS/RCS). This provides real-time control and visibility. The R-bot Four-way Shuttle and H-bot Vertical Bidirectional Shuttle work together to form a Six-way shuttle system. This creates a truly Automatic 3D warehouse. Traditional racking offers limited automation capabilities, primarily relying on manual inventory management.

2. Flexibility and Scalability: Adapting to Evolving Warehouse Needs and Inventory Demands

Zikoo’s pallet shuttle systems offer exceptional flexibility and scalability. The R-bot supports various pallet sizes, including European, American, and Japanese standards. This allows adaptation to diverse inventory. Systems can be easily expanded by adding more shuttles, future-proofing your investment. Traditional racking modifications often require significant structural changes, limiting scalability.

If you’re interested, check 《Six-Way Shuttle Powers Dense Storage: Breaking Space Limitations》

Making the Right Choice: Recommendations for Specific Warehouse Environments and Business Objectives

Selecting the ideal storage solution depends on your unique operational demands. We provide tailored recommendations to ensure maximum efficiency and return on investment. Consider your specific industry and growth projections.

For high-volume, high-density storage needs, such as in e-commerce or cold chain logistics, a pallet shuttle system is often superior. Our R-bot and H-bot combination excels in these environments, offering solutions like the Cold Chain Custom Solution with -25℃ low-temperature batteries. For new energy industries, our New Energy Custom Solution ensures material compatibility. Traditional racking is suitable for operations with diverse SKUs, lower throughput requirements, or limited budgets. We recommend a comprehensive analysis of your current and future needs to determine the best fit.

If you’re interested, check 《Revolutionizing Cold Chain Logistics: Zikoo Robotics Six-Way Shuttle Powers High-Density, High-Efficiency Warehousing》

If you’re interested, check 《Six-Way Shuttle: The Smart Warehousing Tool for Cost Reduction and Efficiency》

Ready to Elevate Your Warehouse Operations?

Upgrade your warehouse with Zikoo Smart Technology Co., Ltd.’s intelligent automation solutions. Contact us today for a personalized consultation. Discover how our R-bot Four-way Shuttles and H-bot Vertical Bidirectional Shuttles can optimize your storage density, efficiency, and overall profitability.

Email: [email protected]

Phone: (+86)-19941778955

What are the primary benefits of a pallet shuttle system over traditional racking?

Pallet shuttle systems deliver significantly higher storage density, faster throughput, reduced labor costs through automation, and improved inventory accuracy compared to traditional racking. They are particularly beneficial for high-volume, dense storage applications.

Is traditional racking still relevant in an era of warehouse automation?

Yes, traditional racking remains relevant and cost-effective for many applications, especially for lower-volume storage, diverse SKU mixes, or when budget constraints limit automation investment. It offers simplicity and direct access to every pallet position.

How do Zikoo’s R-bot and H-bot enhance pallet shuttle system performance?

Zikoo’s R-bot Four-way Shuttle provides flexible, intelligent autonomous handling within racking lanes, while the H-bot Vertical Bidirectional Shuttle acts as a ‘vertical transportation hub.’ Together, they create a Six-way shuttle system, drastically improving throughput and space utilization in dense storage scenarios, suitable for various industries including cold chain and e-commerce.

What factors should I consider when deciding between pallet shuttle and traditional racking?

Key factors include your required storage density, desired throughput, available budget, labor costs, type of inventory (SKU variety, pallet size), future scalability needs, and the level of automation you wish to implement. A thorough analysis of your operational requirements is crucial for an informed decision.