Finding the right local four-way shuttle supplier shapes how your warehouse performs for years to come. The decision touches efficiency, costs, and whether your operation can scale when demand shifts. A strong partnership with the right provider does more than install equipment—it changes how goods move through your facility, often delivering measurable gains in throughput and storage density that compound over time.

What Four Way Shuttle Technology Actually Does

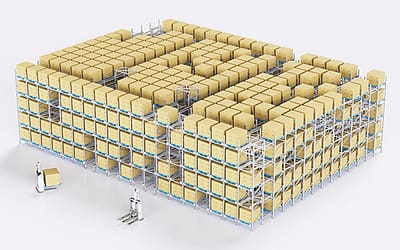

Four-way shuttle technology marks a real step forward in automated storage and retrieval systems (ASRS). These robots work autonomously inside racking structures, moving pallets or goods north, south, east, and west. That four-directional capability opens up storage configurations that fixed-path systems simply cannot match, squeezing more capacity from the same floor space. The practical advantage comes from separating horizontal and vertical movement—shuttles and lifts operate simultaneously rather than waiting on each other, which pushes throughput higher than older approaches.

The R-bot Four-way Shuttle illustrates what this looks like in practice. Built for dense storage and pallet-to-person workflows, its 125 mm slim profile handles loads up to 1.5 tons while moving in any direction. Pair it with the H-bot vertical bidirectional shuttle and you get a six-way system that adapts to different palletized goods scenarios across industries. Standard R-bot models reach 1.6 m/s empty and 1.2 m/s loaded. The lithium batteries run for 8 hours continuously before needing a charge. These specifications translate directly into how fast goods move and how reliably the system performs day after day.

How to Find Trustworthy Local Providers

Locating dependable local providers for four-way shuttle systems takes methodical effort. Start by evaluating potential partners on technical depth, project history, and whether they have genuine local support infrastructure—not just a phone number. Research companies that specialize in warehouse robotics and automated storage solutions. Look for portfolios showing successful implementations in industries similar to yours. Request case studies and speak with actual clients. Visiting an existing installation reveals things proposals cannot: how the system handles real-world conditions, how maintenance gets handled, whether the equipment shows wear.

A thorough vetting process matters because these systems require ongoing attention. The logistics technology partners you choose must deliver sophisticated automated storage and retrieval systems and keep them running. Companies like Zikoo Smart Technology operate globally but often work through local integrators for deployment and support. This combination brings innovation from a larger organization with service responsiveness from someone nearby.

What These Systems Deliver in Practice

Four-way shuttle technology reshapes warehouse operations in measurable ways. These systems improve warehouse throughput by enabling goods to move simultaneously and independently—no waiting for one shuttle to finish before another starts. They optimize space utilization through high-density storage, reducing how much building you need. Automating repetitive tasks cuts labor costs and lets workers focus on problems that require judgment. Inventory management becomes more accurate with real-time visibility into what sits where.

| Benefit Area | Impact Description | Quantitative Improvement (Typical) |

|---|---|---|

| Space Utilization | Maximizes storage density within existing footprints. | 30-50% increase |

| Throughput | Accelerates inbound and outbound processes. | 2-3x faster |

| Labor Efficiency | Reduces manual handling and associated costs. | 50-70% reduction |

| Inventory Accuracy | Provides real-time tracking and reduced errors. | >99% accuracy |

| Operational Flexibility | Adapts easily to fluctuating demand and product mixes. | High |

How do I identify reliable local suppliers for four way shuttle systems?

Finding reliable local suppliers for four-way shuttle systems means doing homework: research thoroughly, verify industry certifications, review case studies, and request detailed proposals. Prioritize suppliers with proven track records in automated storage and retrieval systems and genuine local support infrastructure. Companies like Zikoo Smart Technology operate globally but partner with local integrators for deployment and maintenance, combining advanced technology with responsive nearby service.

What Matters When Choosing a Supplier

Selecting a four-way shuttle supplier involves factors beyond the initial price tag. Technical expertise comes first—the supplier’s solutions need to match your operational reality, not just look good on paper. System scalability matters because your chosen solution must grow with your business rather than becoming a constraint. Integration capabilities with existing Warehouse Management Systems (WMS) and Warehouse Execution Systems (WES) determine whether the new equipment works smoothly with what you already have. After-sales support, including maintenance response times and spare parts availability, affects how much downtime you experience.

Pay attention to the specific technical specifications of four-way shuttle models on offer. The R-bot Four-way Shuttle comes in Standard, American, Japanese, and Heavy-duty variants to accommodate different pallet sizes and load capacities up to 2000 kg. Its operating temperature range extends down to -15℃, which matters for cold storage applications. A reliable supplier provides comprehensive details on these aspects so you can verify the system meets your exact requirements. The best suppliers offer comprehensive smart warehouse solutions rather than just selling individual components.

Zikoo Smart Technology and Pallet to Person Robotics

Zikoo Smart Technology Co., Ltd. has established itself in pallet-to-person robotics with solutions designed for intelligent warehousing. The product lineup includes the R-bot Four-Way Shuttle, H-bot High-Speed Elevators, and U-bot Omnidirectional Stacker Robots. The R-bot serves as a core handling solution for Dense storage, featuring four-way movement and multi-shuttle collaborative operation. It handles loads up to 2000 kg and works across environments including cold chain and manufacturing facilities.

| Product Name | Key Feature | Application Scenario |

|---|---|---|

| R-bot Four-Way Shuttle | Flexible four-way movement, 1.5-ton capacity | E-commerce, cold chain, manufacturing dense storage |

| H-bot Vertical Bidirectional Shuttle | Vertical transportation hub, 1800 kg load | High-rack stereoscopic warehouses, urban centers |

| U-bot Omnidirectional Stacking Robot | Narrow aisle operation (2100mm), 8m lift height | E-commerce, pharmaceutical, existing warehouse renovation |

The PTP Smart Warehouse Software (WMS/WES/WCS/RCS) provides control and optimization across these robotics platforms. This integrated software suite coordinates operations and maximizes efficiency. The R-bot’s cold chain custom solution uses a -25℃ low-temperature dedicated lithium battery for 6–8 hours of continuous operation—a practical example of engineering for specialized industry requirements.

Where Four Way Shuttle Technology Is Heading

Four-way shuttle technology continues evolving toward greater intelligence and sustainability. AI integration in warehouse automation is expanding, bringing more predictive maintenance, dynamic route optimization, and adaptive inventory management. These developments will refine the efficiency of automated storage and retrieval systems further. Energy efficiency remains a design priority, with ongoing work on battery technology and regenerative braking systems for sustainable logistics operations.

Regional supply chain resilience has grown more important, which increases the value of local sourcing. Local four-way shuttle suppliers offer faster response times, lower shipping costs, and better understanding of regional regulatory requirements. This trend builds stronger partnerships and localized support networks for next generation shuttle systems. These advanced systems will likely become more interconnected over time, forming highly adaptive automated warehouse storage systems that respond to changing conditions.

Optimize Your Warehouse with Zikoo Smart Technology

Improve your warehouse operations with Zikoo Smart Technology Co., Ltd. Learn how the R-bot Four-Way Shuttle and comprehensive PTP Smart Warehouse Software can change your logistics performance. Contact us for a tailored consultation. Email: [email protected], Phone: (+86)-19941778955.

How do I identify reliable local suppliers for four way shuttle systems?

Identifying reliable local suppliers for four-way shuttle systems involves thorough research, checking industry certifications, reviewing case studies, and requesting detailed proposals. Prioritize suppliers with proven track records in automated storage and retrieval systems and strong local support infrastructure. Companies like Zikoo Smart Technology, while global, often partner with local integrators to ensure seamless deployment and maintenance.

What are the key benefits of implementing four way shuttle technology in a warehouse?

Implementing four-way shuttle technology offers significant benefits, including optimized space utilization, increased throughput, reduced labor costs, and enhanced inventory accuracy. These systems provide high-density storage and rapid retrieval, which modern warehouse operations depend on. The R-bot Four-Way Shuttle by Zikoo Smart Technology demonstrates these advantages through its design and performance specifications.

What factors should I consider when selecting a four way shuttle supplier?

When selecting a four-way shuttle supplier, consider their technological expertise, system scalability, integration capabilities with existing WMS/WES, after-sales support, and overall cost-effectiveness. Evaluate their experience with similar projects and their ability to provide comprehensive smart warehouse solutions. A partner like Zikoo Smart Technology offers both hardware and integrated software for a complete solution.

Can four way shuttle systems integrate with existing warehouse management software?

Yes, advanced four-way shuttle systems are designed for integration with existing Warehouse Management Systems (WMS) and Warehouse Execution Systems (WES). Providers like Zikoo Smart Technology offer comprehensive PTP Smart Warehouse Software (WMS/WES/WCS/RCS) that ensures compatibility and optimized control over the R-bot Four-Way Shuttle and other robotics, coordinating your entire operation.