Warehouses are getting squeezed from every direction right now. E-commerce keeps pushing volume expectations higher while supply chains grow more tangled by the quarter. The old ways of moving pallets around just can’t keep pace anymore. Four way shuttle systems have emerged as a practical answer to these pressures, and Zikoo’s R-bot represents what this technology can actually deliver when designed with real warehouse constraints in mind.

Optimizing Space Utilization with Shuttle Technology

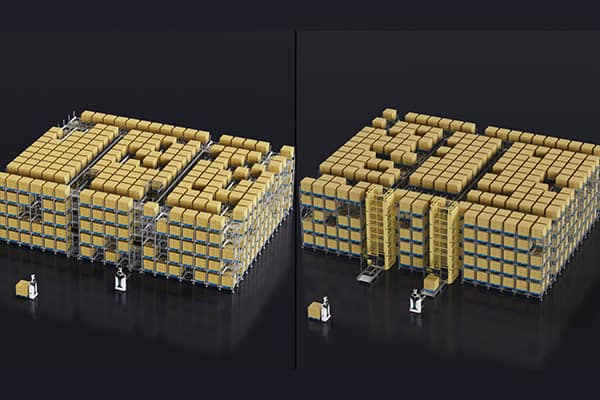

Four way shuttle technology changes how warehouses think about available cubic footage. These systems enable deep lane storage configurations that pack pallets far more tightly than conventional racking ever could. Zikoo’s R-bot Four-way Shuttle measures just 125 mm thick and handles loads up to 1.5 tons, which means it slips through gaps that would stop bulkier equipment cold. That slim profile translates directly into recovered floor space and taller storage configurations.

Pairing the R-bot with the H-bot Vertical Bidirectional Shuttle creates something more powerful than either unit alone. This combination forms a six-way shuttle system that moves goods through a true three-dimensional network. Vertical transport becomes just another direction rather than a bottleneck.

For further insights into maximizing storage density, consider reading 《Six-Way Shuttle Powers Dense Storage: Breaking Space Limitations》.

Accelerating Throughput and Order Fulfillment

Speed matters when customers expect next-day delivery as standard. Four way shuttle systems attack cycle times by letting multiple shuttles work the same zone simultaneously. While one R-bot handles putaway, another pulls picks from a neighboring lane. No waiting, no traffic jams in the aisles.

The numbers back this up. R-bot models hit 1.6 m/s running empty and maintain 1.2 m/s under full load. That velocity compounds across hundreds of daily movements into measurably faster order processing.

Key Benefits of Implementing a Four Way Shuttle System

The case for these systems builds on several fronts. Automation handles the repetitive stuff that wears people down and invites mistakes. Error rates drop when software controls placement and retrieval. Safety improves because fewer workers need to operate near moving equipment. Productivity gains follow naturally from all of these factors working together.

Enhancing Operational Agility and Scalability

Markets shift. Seasonal peaks hit. Product mixes change. Warehouses need equipment that can roll with these punches rather than locking operations into rigid configurations.

Four way shuttle systems are built modular from the ground up. Adding capacity means deploying more shuttles, not ripping out infrastructure. Zikoo’s R-bot handles various pallet sizes and adapts to different storage scenarios. The same technology works in an e-commerce fulfillment center or a cold chain facility operating at -25°C. That flexibility protects the investment as business requirements evolve.

Integrating Four Way Shuttles with Warehouse Software

Hardware alone only gets you partway there. Zikoo’s PTP Smart Warehouse Software (WMS/WES/WCS/RCS) serves as the brain coordinating every shuttle movement. The system optimizes where inventory sits, plans efficient routes, allocates tasks across the fleet, and catches problems before they cascade.

Real-time visibility into operations replaces guesswork with data. Managers see what’s happening and can adjust on the fly rather than discovering issues after the fact.

Factors to Consider When Integrating a Four Way Shuttle

Getting integration right requires homework upfront. Existing racking and floor conditions need assessment for compatibility. Inventory profiles and throughput targets should drive shuttle model selection. Current warehouse management systems must connect cleanly with the new automation layer. Our team walks through these considerations with each customer because shortcuts here create headaches later.

Comparative Advantages Over Traditional Automation

The comparison with older approaches reveals clear differences. Forklifts demand wide aisles that eat up valuable floor space. Conventional automated storage and retrieval systems work well but struggle to match the flexibility that four-way shuttle configurations provide.

Shuttles access inventory more dynamically. They exploit vertical space more fully. And when requirements change, the system adapts without major reconstruction.

How a Four Way Shuttle System Compares to Traditional Automation

| Feature | Four Way Shuttle System | Traditional AS/RS | Forklift Operations |

|---|---|---|---|

| Space Utilization | High density storage | Moderate to High | Low |

| Speed | High | Moderate | Low |

| Scalability | High | Moderate | Low |

| Flexibility | High | Moderate | Low |

| Labor Costs | Low | Moderate | High |

For a detailed comparison of different automation technologies, you might find 《Stacker Crane vs Four-Way Shuttle: Which Fits Your ASRS Warehouse Best》 insightful.

Frequently Asked Questions About Four Way Shuttle Systems

What specifically makes a four way shuttle system more efficient than conventional pallet racking?

A four-way shuttle system enables deep lane storage and full vertical space utilization while shuttles move independently in all four directions. That multi-directional capability cuts travel times dramatically. Static pallet racking limits access to single aisles, which creates bottlenecks that shuttles simply bypass.

Can Zikoo’s R-bot Four Way Shuttle integrate with existing warehouse infrastructure?

Yes. The R-bot was designed with integration flexibility in mind. Our PTP Smart Warehouse Software (WMS/WES/WCS/RCS) connects with existing systems to coordinate material flow and inventory management. Our team evaluates current infrastructure during planning to identify any compatibility considerations before installation begins.

What is the typical return on investment for implementing a four way shuttle system?

ROI for a four way pallet shuttle system depends on the specific operation, but the drivers are consistent. Higher storage density, lower labor requirements, faster fulfillment, and fewer errors all contribute. Many operations see meaningful cost reductions and productivity improvements within a few years, though exact timelines vary with scale and starting conditions.

How does a four way shuttle system improve safety in the warehouse environment?

warehouse shuttle system reduce how often workers need to be near heavy equipment in active zones. Fewer forklift movements mean fewer collision risks. Automated handling eliminates manual lifting injuries. The net result is a safer facility with lower incident rates.

Transform Your Warehouse Operations with Zikoo Smart Technology

Four way shuttle systems have proven their value across enough installations now that the technology feels mature rather than experimental. Zikoo’s R-bot Four-way Shuttle paired with our PTP Smart Warehouse Software addresses the core challenges facing modern warehouses. The combination delivers on efficiency, scales with growth, and adapts as requirements shift.

Ready to achieve unparalleled efficiency and scalability in your warehouse? Zikoo Smart Technology Co., Ltd. offers cutting-edge pallet-to-person robotics, including the R-bot Four-Way Shuttle and the PTP Smart Warehouse Software. Discover how our integrated solutions can revolutionize your material handling. Contact us today for a personalized consultation and unlock the full potential of your logistics operations. Email: [email protected] | Phone: (+86)-19941778955