After years of walking production floors and poring over pick logs at 2 a.m., I can say this with confidence: raw material management makes or breaks a plant. When it’s sloppy, costs creep, lines idle, and counts drift. When it’s tight, the whole operation breathes easier. Automated storage has become my go-to lever because it cuts straight through the usual pain points, tightening accuracy, reclaiming space, and lifting throughput. Below, I break down how these systems reshape raw material handling and, frankly, why they’ve become a quiet advantage for manufacturers who adopt them early.

Why Inefficient Raw Material Management Hinders Manufacturing Productivity

Manufacturing depends on steady, predictable material flow. When that stream clogs, the shockwaves hit scheduling, labor allocation, and output. Old-school methods bring friction that slows work and piles on cost.

1. Understanding the Challenges in Traditional Raw Material Storage

Manual storage introduces too many variables. I have seen items mis-scanned or shelved in the wrong bay, then hours vanish hunting for them. As volumes grow, the square footage demanded by conventional racks becomes a hard constraint. Without real-time visibility, planners are flying half blind, which slows decisions and blunts the response to shifting demand or supply hiccups.

2. The Cost Implications of Suboptimal Inventory Handling

Poor inventory handling is expensive in both directions. Excess stock traps capital, inflates storage costs, and risks obsolescence. Running too lean causes line stoppages and missed ship windows. On top of that, manual search, retrieval, and verification consume labor that adds up fast. Those hidden inefficiencies chip away at margins and make it harder to compete.

3. Bottlenecks and Delays in Production Workflows

When materials do not arrive at the line on time, machines sit and crews wait. Throughput suffers, and daily output targets become harder to hit. Disorganized storage and slow retrieval multiply the delays, keeping plants from finding their natural pace.

How Automated Storage Solutions Revolutionize Raw Material Flow

Automation tackles these issues head-on. By standardizing how materials are stored, tracked, and moved, it trims waste, raises accuracy, and gives operations the agility they need.

1. Enhancing Inventory Accuracy and Visibility with Automation

Automated systems assign each item a unique identifier and track it from receipt through consumption. That removes manual error and puts live stock levels and locations at your fingertips. The result is fewer discrepancies and far less risk of stockouts or overstocking.

2. Optimizing Warehouse Space Utilization for Raw Materials

Automated storage packs inventory tighter, especially by using vertical space. It often cuts the footprint required by up to 85%. Plants can store more in the same area or repurpose valuable floor space for production or kitting.

3. Boosting Operational Efficiency and Throughput in Manufacturing

Robots and shuttles retrieve and deliver faster than a person walking aisles with a pallet jack. That speed trims wait time at the line, reduces delays, and raises throughput. Over a shift, those minutes turn into extra completed orders.

If you’re interested, check The Future of Automated Warehousing: From ASRS Warehouse to Fully Intelligent Storage.

4. Reducing Labor Costs and Improving Workplace Safety

Automation offloads repetitive, heavy work. That lowers labor spend on routine moves and eases training demands. It also keeps people farther from forklifts, high lifts, and hazardous materials, which improves safety and reduces incidents.

Key Technologies Driving Automated Raw Material Storage

Modern systems blend several technologies to get the job done. Together, they create a consistent, high-density, and data-rich storage backbone.

1. Exploring Pallet-to-Person Robotic Systems

Pallet-to-person systems bring pallets to the operator, not the other way around. That simple inversion trims travel, speeds picks, and reduces fatigue. Because they scale and adapt well, they slot into a wide range of manufacturing setups.

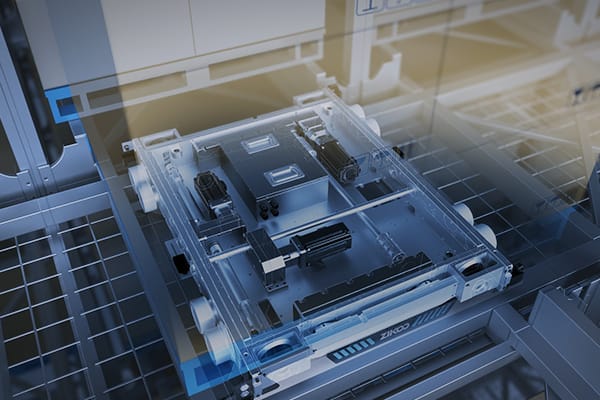

2. The Role of Four-Way Shuttles in Dense Storage (Zikoo R-bot)

Four-Way Pallet Shuttle systems, such as the Zikoo R-bot, are central to high-density raw material storage. These intelligent robots move autonomously in four directions, enabling flexible access to any pallet position within a rack structure. The R-bot’s slim design (125 mm body thickness) and robust load capacity (up to 1.5 tons) make it ideal for maximizing storage volume. It supports various pallet sizes including Standard (1200 × 800–1000 mm), American (1016 × 1219 mm), and Japanese (1100 × 1100 mm). R-bots are particularly effective for dense storage in manufacturing raw material warehouses and cold chain environments.

Zikoo R-bot Four-way Shuttle Specifications

| Model Option | Weight (kg) | Rated Load (kg) | Body Dimensions (L×W×H mm) | Supported Pallet Sizes (mm) | Empty Speed (m/s) | Loaded Speed (m/s) | Battery Life (hours) | Operating Temp (°C) |

|---|---|---|---|---|---|---|---|---|

| Standard (R1200B) | 270 | 1200 | 1000 × 972 × 125 | 1200 × 800–1000 | 1.6 | 1.2 | 8 | -15 |

| American (R1200A) | 265 | 1200 | 1192 × 840 × 125 | 1016 × 1219 | 1.6 | 1.2 | 8 | -15 |

| Japanese (R1500J) | 270 | 1500 | 1192 × 900 × 125 | 1100 × 1100 | 1.6 | 1.2 | 8 | -15 |

| Heavy-duty (R1500B) | 275 | 1500 | 1192 × 972 × 125 | 1200 | 1.6 | 1.2 | 8 | -15 |

| Heavy-duty Large Pallet (R2000B) | 400 | 2000 | 1250 × 1300 × 150 | 1400 | 1.35 | 1.0 | 7 | -15 |

3. Vertical Transportation Solutions for High-Rack Warehouses (Zikoo H-bot)

The Zikoo H-bot Vertical Two-Way Shuttle acts as a vertical transportation hub, integrating with R-bots to form a six-way shuttle system. This creates a three-dimensional warehousing network for efficient movement across all axes. With a compact footprint and ±1 mm positioning accuracy, H-bots handle vertical cargo transfer in high-rack warehouses with precision. They fit well in urban warehousing centers and renovation projects where space is tight.

Zikoo H-bot Vertical Bidirectional Shuttle Specifications

| Model Option | Body Weight (kg) | Body Dimensions (L×W×H mm) | Rated Load (kg) | Supported Pallets (mm) | Empty Speed (m/s) | Loaded Speed (m/s) | Empty Accel (m/s²) | Loaded Accel (m/s²) | Operating Temp (°C) |

| :———————- | :————— | :————————- | :————– | :——————— | :—————- | :—————– | :—————– | :—————— |

| Standard (H1800B) | 345 | 1300 × 1464 × 288 | 1800 | 1200 × 800–1200 | 1 | 0.5 | 1 | 0.3 | -25 to 45 |

| American (H1800A) | 325 | 1300 × 1332 × 288 | 1800 | 1016 × 1219 | 1 | 0.5 | 1 | 0.3 | -25 to 45 |

| Japanese (H1800J) | 335 | 1300 × 1392 × 288 | 1800 | 1100 × 1100 | 1 | 0.5 | 1 | 0.3 | -25 to 45 |

| Heavy-duty Large Pallet | Custom | Custom | Custom | Custom | Custom | Custom | Custom | Custom | -25 to 45 |

4. Omnidirectional Stacking Robots for Narrow Aisle Efficiency (Zikoo U-bot)

The Zikoo U-bot Omnidirectional Stacker Robot is built for narrow aisles, working in spaces as tight as 2100 mm. Its U-shaped frame and tiny turning radius give it excellent maneuverability in close quarters. With lift heights up to 8 meters and a 1000 kg load, it fits high-density storage for raw materials or finished goods. U-bots can also team up with AMRs for end-to-end material movement.

Zikoo U-bot Omnidirectional Stacking Robot Specifications

| Model | Dimensions (mm) | Rated Load (kg) | Self-weight (kg) | Lifting Height (mm) | Min. Aisle Width (mm) | Positioning Accuracy (mm) | Battery Configuration | Continuous Operation (hours) |

|---|---|---|---|---|---|---|---|---|

| U1045 | 2198 × 1784 × 2100 | 1000 | 3000 | 4500 | 2100 | ±10 | 48 V / 210 Ah LiFePO₄ | 6–8 |

| U1060 | 2198 × 1820 × 2685 | 1000 | 3300 | 6000 | 2140 | ±10 | 48 V / 210 Ah LiFePO₄ | 6–8 |

| U1080 | 2198 × 1820 × 3465 | 1000 | 3500 | 8000 | 2140 | ±10 | 48 V / 210 Ah LiFePO₄ | 6–8 |

5. Integrated Software for Smart Warehouse Management (Zikoo PTP Smart Warehouse Software)

Solid hardware needs strong software. Zikoo’s PTP Smart Warehouse Software (WMS/WES/WCS/RCS) manages inventory, optimizes storage locations, and coordinates robot movement across the fleet. The platform keeps operations running smoothly, offers in-depth data analytics, and supports smarter decisions about raw material flow. It is the backbone for a flexible, smart logistics ecosystem.

If you’re interested, check PTP Intelligent Warehousing Platform: Building a Flexible and Smart Logistics Ecosystem.

Implementing Automated Storage for Raw Material Success

Getting automation right is a project, not a purchase. A structured rollout protects uptime and accelerates payback.

1. Assessing Your Manufacturing Facility’s Needs and Infrastructure

Start with a clear picture of the current state. Look at storage capacity, flow patterns, and production demand. Validate constraints like floor load, clear height, and available power to align technology with the building. That baseline guides the right solution set.

2. Planning and Designing an Automated Raw Material Storage System

Choose the robotic mix and lay out the warehouse to match density, throughput, and material characteristics. Our engineers define rack design, robot paths, and handoff points to production lines with precision. The end goal is a design that maps cleanly to your operational targets.

If you’re interested, check From Concept to Deployment: Zikoo’s Integrated Shuttle Strategy.

3. Overcoming Common Implementation Challenges

Legacy integrations and change management can trip teams up. We manage projects in phases, train crews thoroughly, and stay close through go-live to limit disruption. Ongoing technical support keeps the system stable as volumes and SKUs evolve.

4. Measuring the Return on Investment for Automation

Track the wins. Labor saved, space recovered, and inventory accuracy improved are the big three, with higher throughput and fewer errors accelerating payback. The financial lift holds over time as the system keeps waste down and output steady.

The Future of Raw Material Management in Smart Manufacturing

Manufacturing is becoming more connected and data-driven, and storage is part of that shift. Automated systems help plants stay resilient while competing on speed and cost.

1. Integrating Automation with Industry 4.0 Principles

Automated storage fits neatly into Industry 4.0. It generates data that feeds optimization, and it ties into AI-based planning and IoT sensors to create a connected operation. That foundation enables predictive maintenance and more responsive supply chain control.

2. Adapting to Evolving Supply Chain Demands

Markets swing, SKUs change, and volumes spike. Automated storage handles that variability with modular growth and reconfigurable layouts. As needs shift, capacity and flow can be tuned without rebuilding the warehouse from scratch.

3. Sustaining Competitive Advantage Through Advanced Automation

Plants that commit to advanced automation lower operating costs, shorten cycles, and improve quality. Strong material control translates to faster time-to-market and better customer experience. It is a pragmatic bet on future growth and share gains.

Unlock the Future of Raw Material Management

Ready to upgrade your raw material management and boost manufacturing productivity? Zikoo Smart Technology offers cutting-edge automated storage solutions designed for efficiency, accuracy, and scalability. Contact us today to discuss how our R-bot, H-bot, U-bot, and PTP Smart Warehouse Software can revolutionize your operations. Reach out via email at [email protected] or call us at (+86)-19941778955.

FAQs

1. What are the primary benefits of automated storage solutions for raw materials?

They raise inventory accuracy, make better use of warehouse space, increase operational efficiency, and reduce labor costs. By cutting down manual handling, they also improve safety on the floor.

2. How do automated systems improve inventory accuracy?

Each item is tagged with a unique identifier and tracked in real time, so location and status are always current. That removes manual error, keeps stock counts precise, and ensures materials remain accounted for.

3. Can automated storage solutions be integrated into existing manufacturing facilities?

Yes. Many systems are designed for flexible integration. Zikoo’s platforms can be tailored to existing layouts and infrastructure, which helps avoid major structural changes.

4. What types of raw materials are best suited for automated storage?

A wide range works well, especially palletized goods, components, and items that benefit from high-density storage, precise tracking, or fast retrieval. This includes cold storage environments.

5. How does Zikoo Smart Technology support the implementation of these solutions?

Zikoo provides end-to-end support that covers initial assessment, system design, implementation, training, and ongoing technical backing. The combined software and robotics stack keeps operations coordinated and delivers measurable ROI.