As warehouse operations grow increasingly complex, traditional rigid structures like stacker cranes and conveyor lines are showing their limitations. Zikoo Robotics leads a new wave of logistics innovation by introducing the Six-way shuttle system, fundamentally reshaping the architecture of the Automatic 3D warehouse.

By embedding the lifting mechanism within the rack itself, the Six-way shuttle system removes the dependency on fixed vertical conveyors. It empowers a new level of routing flexibility and intelligent task scheduling. Integrated with Zikoo’s proprietary Four-way shuttle (R-bot) and H-bot vertical lift, the system enables seamless multi-directional movement—up, down, left, right—providing high adaptability for dynamic operations.

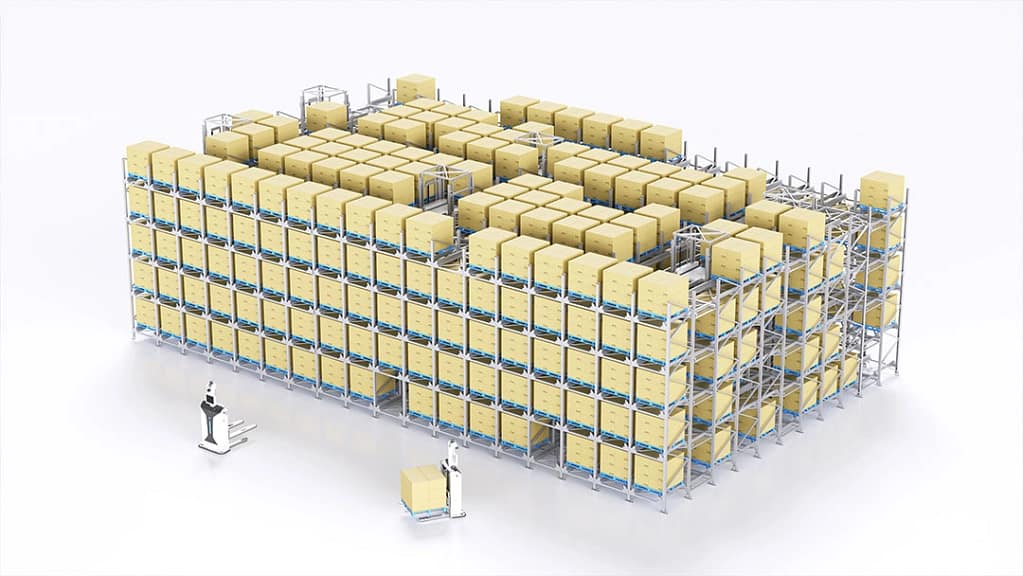

This architecture excels in Dense storage environments, achieving up to 80% space efficiency by reducing idle aisle space. More importantly, the robot-centric design supports high-frequency, multi-SKU applications typical in Pallet Smart Warehouse operations for industries like food, e-commerce, and apparel.

Zikoo’s modular structure facilitates faster deployment and easier expansion, backed by cross-platform compatibility with global WMS/WCS systems. It is a forward-looking solution that supports the Digital transformation of warehousing while maintaining agility and cost-efficiency.

As a leading innovator in palletized logistics robotics, Zikoo Robotics continues to push the boundaries of intelligent intralogistics. The Six-way shuttle system is not just a product—it’s a strategic enabler of flexible, scalable, and smart Pallet Smart Warehouse systems designed for the global market.

Keywords:

Six-way shuttle,Four-way shuttle,Dense storage,Pallet Smart Warehouse,Digital transformation of warehousing,Automatic 3D warehouse