Pick the right picking robot and the building runs like clockwork. Pick the wrong one and costs creep into places they do not belong. After years of tuning systems around mixed inventories, we have learned that each product category asks for a different kind of automation. What follows maps robot capabilities to inventory traits and operational realities, so you can choose with confidence and lift throughput, accuracy, and overall supply chain resilience.

Understanding Different Inventory Types and Their Picking Challenges

1. Identifying the characteristics of diverse inventory categories

Modern warehouses handle an extensive array of products, each with distinct physical attributes and storage requirements. I start by sorting inventory by size, weight, fragility, and environmental needs. Small, lightweight items like e-commerce goods benefit from high-speed, precise handling. Heavy, bulky industrial components call for robust lifting and transport capabilities. Perishable goods, such as food or pharmaceuticals, require strict temperature control and rapid movement to maintain integrity. Getting these characteristics right is the first step in selecting suitable automation.

2. Analyzing common picking challenges in modern warehouses

Warehouses face numerous picking challenges that directly impact efficiency and profitability. Space utilization is a constant concern, particularly in dense urban locations where real estate is expensive. Manual picking often drives up labor costs, introduces error, and slows throughput during peak seasons. Managing diverse SKUs, fulfilling complex order profiles, and protecting products in specialized environments like cold chains or hazardous material storage add more complexity. These realities make advanced robotic solutions a practical necessity.

Key Factors for Selecting Optimal Picking Robots

1. Evaluating warehouse layout and space utilization requirements

The physical layout of a warehouse shapes which robot will perform well. High-density storage systems benefit from robots designed for narrow aisles or vertical space optimization. We weigh ceiling height, aisle width, and existing racking infrastructure. By maximizing vertical space, operations reduce overall footprint, which is a clear advantage for many sites.

2. Assessing inventory characteristics and handling needs

The nature of the inventory directly influences robot selection. Fragile items need gentle handling mechanisms, while heavy loads require significant lifting capacity. Item dimensions and shapes determine gripper types and robotic arm configurations. For inventory in the cold chain, robots must be engineered to withstand extreme temperatures. We align the robot’s capabilities precisely with product handling requirements.

3. Considering operational efficiency and throughput demands

Throughput targets define what a picking system must deliver. High-volume operations, especially in e-commerce, need robots capable of rapid, continuous picking. We analyze order profiles, peak demand, and service levels to size the speed and capacity of the solution. The aim is maximum efficiency without compromising accuracy.

4. Understanding integration capabilities with existing systems

Tight integration with warehouse management systems (WMS), warehouse execution systems (WES), and warehouse control systems (WCS) is vital. Robots should communicate reliably with these platforms to coordinate movements and keep inventory records accurate. We evaluate compatibility with current IT infrastructure to avoid disruptions and enable a smooth rollout. Integration keeps operations cohesive and intelligent. If you’re interested, check PTP Intelligent Warehouse Software Empowers Enterprises for Smart Upgrades

Comparing Zikoo’s Picking Robot Solutions for Diverse Inventories

Zikoo Smart Technology Co., Ltd. offers a comprehensive range of pallet-to-person robotics designed to address varied inventory types and operational demands. Our solutions enhance efficiency, optimize space, and improve accuracy across diverse industries.

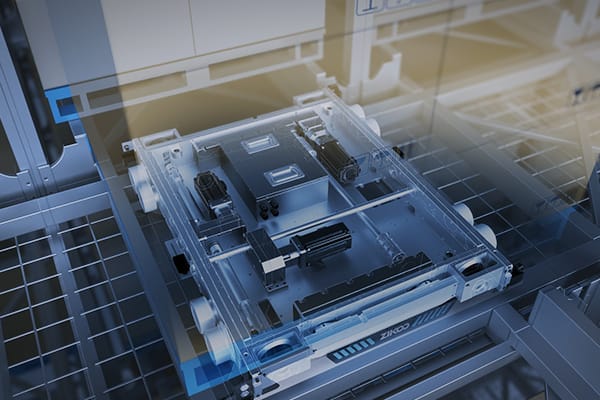

1. R-bot Four-way Shuttle: Ideal for dense pallet storage and specific environments

The R-bot Four-way Shuttle is a core handling solution for dense storage, optimized for pallet-to-person scenarios. Its slim 125 mm body and up to 1.5-ton load capacity support flexible four-way movement and multi-shuttle collaboration. Paired with the H-bot vertical bidirectional shuttle, it forms a six-way shuttle system that adapts to a wide range of palletized goods.

R-bot Four-way Shuttle Specifications

| Model | Weight (kg) | Rated Load (kg) | Dimensions (L×W×H mm) | Supported Pallet Sizes (mm) | Empty Speed (m/s) | Loaded Speed (m/s) | Battery Specs | Continuous Operation (hours) | Operating Temp (°C) |

|---|---|---|---|---|---|---|---|---|---|

| Standard (R1200B) | 270 | 1200 | 1000 × 972 × 125 | 1200 × 800–1000 | 1.6 | 1.2 | 51.2V/40Ah or 30Ah | 8 | -15 to 45 |

| American (R1200A) | 265 | 1200 | 1192 × 840 × 125 | 1016 × 1219 | 1.6 | 1.2 | 51.2V/40Ah or 30Ah | 8 | -15 to 45 |

| Japanese (R1500J) | 270 | 1500 | 1192 × 900 × 125 | 1100 × 1100 | 1.6 | 1.2 | 51.2V/40Ah or 30Ah | 8 | -15 to 45 |

| Heavy-duty (R1500B) | 275 | 1500 | 1192 × 972 × 125 | 1200 | 1.6 | 1.2 | 51.2V/40Ah or 30Ah | 8 | -15 to 45 |

| Heavy-duty Large Pallet (R2000B) | 400 | 2000 | 1250 × 1300 × 150 | 1400 | 1.35 | 1.0 | 51.2V/40Ah or 30Ah | 7 | -15 to 45 |

Application Scenarios:

* Dense storage in e-commerce warehouses and distribution centers.

* Special environments, including cold chain food storage and pharmaceutical constant temperature warehouses.

* High-density storage of raw materials and finished products in manufacturing.

For cold chain applications, the R-bot offers a custom solution with a -25℃ low-temperature lithium battery, providing 6–8 hours of continuous operation. Its special PCBA coating enhances safety in high-humidity environments. For new energy applications, the vehicle design avoids metal contaminants and uses stainless steel frames. The R-bot is a versatile Four-Way Pallet Shuttle for diverse storage needs. You can learn more about this system by reading The Smart Choice for the Dense Storage Era: Zikoo’s Four-Way Shuttle System.

2. H-bot Vertical Bidirectional Shuttle: Enhancing vertical transportation and system efficiency

The H-bot Vertical Bidirectional Shuttle acts as the “vertical transportation hub” in intelligent warehousing systems. It is designed for pallet-to-person dense storage, occupying only a single storage location. This shuttle integrates with the R-bot Four-way Shuttle to form a three-dimensional warehousing network. The combination significantly enhances overall operational efficiency and throughput.

H-bot Vertical Bidirectional Shuttle Specifications

| Model | Body Weight (kg) | Dimensions (L×W×H mm) | Rated Load (kg) | Supported Pallets (mm) | Empty Speed (m/s) | Loaded Speed (m/s) | Empty Acceleration (m/s²) | Loaded Acceleration (m/s²) | Positioning Accuracy (mm) | Operating Temp (°C) |

|---|---|---|---|---|---|---|---|---|---|---|

| Standard (H1800B) | 345 | 1300 × 1464 × 288 | 1800 | 1200 × 800–1200 | 1 | 0.5 | 1 | 0.3 | ±1 | -25 to 45 |

| American (H1800A) | 325 | 1300 × 1332 × 288 | 1800 | 1016 × 1219 | 1 | 0.5 | 1 | 0.3 | ±1 | -25 to 45 |

| Japanese (H1800J) | 335 | 1300 × 1392 × 288 | 1800 | 1100 × 1100 | 1 | 0.5 | 1 | 0.3 | ±1 | -25 to 45 |

| Heavy-duty Large Pallet (Custom) | Customized | Customized | Customized | Customized | Customized | Customized | Customized | Customized | ±1 | -25 to 45 |

Application Scenarios:

* Vertical cargo transfer in high-rack stereoscopic warehouses.

* Urban warehousing centers or existing warehouse renovation projects.

* Dense storage scenarios requiring improved space utilization.

The H-bot is integral to our six-way shuttle solution, forming a spatial network that dramatically improves throughput. This system is key to maximizing space and velocity. For more details on this system, refer to Six-Way Shuttle System: Multi-Scenario Solutions Redefining Pallet Storage and Picking.

3. U-bot Omnidirectional Stacking Robot: Mastering narrow aisle and high-level storage

The U-bot Omnidirectional Stacking Robot is designed for narrow aisle storage, requiring a minimum aisle width of only 2100 mm. Its U-shaped body and 1370 mm turning radius provide outstanding maneuverability. With a lifting height of 0–8 meters and a 1000 kg rated load, it operates collaboratively with AMRs and robotic arms.

U-bot Omnidirectional Stacking Robot Specifications

| Model | Dimensions (mm) | Rated Load (kg) | Self-weight (kg) | Lifting Height (mm) | Min. Aisle Width (mm) | Driving Positioning Accuracy (mm) | Battery Configuration | Continuous Operation (hours) |

|---|---|---|---|---|---|---|---|---|

| U1045 | 2198 × 1784 × 2100 | 1000 | 3000 | 4500 | 2100 | ±10 | 48V / 210Ah LFP | 6–8 |

| U1060 | 2198 × 1820 × 2685 | 1000 | 3300 | 6000 | 2140 | ±10 | 48V / 210Ah LFP | 6–8 |

| U1080 | 2198 × 1820 × 3465 | 1000 | 3500 | 8000 | 2140 | ±10 | 48V / 210Ah LFP | 6–8 |

Application Scenarios:

* Narrow aisle high-density storage in e-commerce warehouses.

* Constant temperature storage and picking in the pharmaceutical industry.

* Storage of raw materials and finished products in manufacturing.

* Intelligent transformation projects of existing warehouses.

The U-bot uses dual laser SLAM hybrid navigation for safe operation in tight spaces. A 3D depth camera models pallet positions to compensate for deviations. Its rack-and-pinion forward mast structure lifts productivity where aisles leave little room for error. The U-bot is a versatile Omnidirectional Stacker Robot for high-level, narrow-aisle storage.

4. U-bot + AMR Narrow Aisle Picking System: Collaborative solutions for hybrid picking scenarios

The U-bot + AMR Narrow Aisle Picking System delivers an efficient collaborative setup for hybrid “To B palletization” and “To C split-case picking” scenarios. The U-bot handles high-level storage while AMRs manage low-level handling and picking. This vertical functional complementarity improves adaptability for full-category outbound picking.

System Performance Indicators:

* Picking efficiency: ≥300 pieces per hour.

* Inbound and outbound efficiency: ≥80 pallets per hour.

* Storage density improvement: over 30%.

* Positioning accuracy: ±10 mm.

* Minimum aisle width: 2100 mm.

* Supported SKU quantity: up to 10,000.

Application Scenarios:

* Multi-SKU split-case picking in e-commerce warehouses.

* Storage of raw materials and finished products in manufacturing.

* Suspended storage and sorting in the apparel industry.

* Multi-variety, small-batch storage in the pharmaceutical industry.

This approach is especially effective for e-commerce, handling up to 10,000 SKUs with dynamic path planning. In manufacturing, it supports high-density layouts with strong inbound and outbound efficiency. The collaboration of roles optimizes both space and throughput.

Implementing and Optimizing Picking Robot Systems

1. Planning the deployment of robotic solutions in your facility

Successful deployment starts with careful discovery. We begin with a detailed analysis of current operations, pinpointing bottlenecks and improvement opportunities. That includes evaluating existing infrastructure, defining performance metrics, and simulating potential robot workflows. A phased rollout reduces disruption and allows teams to adapt. We align the selected solution with long-term business goals and growth plans.

2. Maximizing performance through software integration and data analysis

Performance depends on solid software integration and an ongoing look at the data. Our PTP Smart Warehouse Software (WMS/WES/WCS/RCS) provides real-time visibility and control over all robotic operations. The platform supports dynamic task assignment, route optimization, and predictive maintenance. Regular analysis of operational data highlights opportunities to refine workflows, helping the system meet or exceed targets. Effective use of data keeps improvements rolling. If you’re interested, check PTP Intelligent Warehousing Platform: Building a Flexible and Smart Logistics Ecosystem.

3. Ensuring scalability and adaptability for future warehouse needs

Warehouses need to flex with shifting demand and growth. Our robotic solutions are built for scalability and adaptability. Modular designs make it straightforward to expand robot fleets and storage capacity. Flexible software configurations accommodate new inventory types or picking strategies. This forward-looking approach protects your automation investment as the business evolves. We build systems that grow with you.

The Future of Inventory Picking with Advanced Robotics

1. Exploring emerging trends in warehouse automation and AI

The future of inventory picking is being shaped by advances in warehouse automation and artificial intelligence. We see stronger machine learning for predictive analytics, vision systems that improve item recognition, and more capable human-robot collaboration. These innovations push efficiency, accuracy, and flexibility higher. Zikoo Robotics continues to integrate these technologies into our solutions.

2. Predicting the impact of robotics on supply chain resilience and efficiency

Robotics will have a profound impact on supply chain resilience and efficiency. By automating repetitive, labor-intensive tasks, robots reduce reliance on manual labor and help offset labor shortages. They accelerate order fulfillment, improve inventory accuracy, and lift overall throughput, creating more responsive supply chains. The resulting edge is real in competitive markets. We believe robotics are essential for building resilient and efficient supply chains.

Partner with Zikoo Robotics for Advanced Picking Solutions

Ready to transform your warehouse operations with intelligent picking robots? Contact Zikoo Smart Technology Co., Ltd. to discuss your inventory challenges and see how our R-bot, H-bot, and U-bot solutions can optimize logistics. Our team will design and implement a tailored system that meets your needs for efficiency, accuracy, and scalability.

Email: [email protected]

Phone: (+86)-19941778955

FAQs

1. What is the typical ROI for investing in picking robots?

The typical Return on Investment (ROI) for picking robots varies by warehouse size, inventory volume, and labor costs. Many businesses see a significant ROI within 1–3 years due to reduced labor expenses, improved accuracy, increased throughput, and better space utilization. Our solutions are built to deliver rapid, measurable returns.

2. Can picking robots operate in cold storage or harsh environments?

Yes, Zikoo’s R-bot Four-way Shuttle includes specialized versions for cold storage, operating efficiently at temperatures as low as -25℃. These robots use low-temperature batteries and enhanced protective coatings to ensure reliable performance in harsh, high-humidity environments.

3. How do I determine the right robot type for my specific inventory?

Start by assessing your inventory’s size, weight, and fragility, then evaluate warehouse layout factors like aisle width and ceiling height, followed by throughput and order profiles. We recommend a detailed consultation with our experts to complete a thorough analysis and recommend the most suitable robotic solution for your needs.

4. What kind of maintenance do picking robots require?

Picking robots require routine preventative maintenance, including software updates, battery checks, and mechanical inspections. Our systems are designed for reliability and easy upkeep, with remote diagnostics and modular components for quick servicing. We offer comprehensive support plans to keep performance steady.

5. How long does it take to integrate a new picking robot system?

Integration timelines depend on warehouse complexity and project scope. A typical deployment can range from a few months to over a year. Our structured process, supported by simulation tools, streamlines implementation and minimizes downtime.