Modern warehouses feel the squeeze on space more than ever, and making the most of existing footprints often decides whether operations stay lean. As inventory grows and real estate costs rise, traditional storage setups hit their limits. We see how important smart space use is for keeping costs under control. Here, we look at how high-density pallet racking systems, especially when paired with advanced automation, can reshape storage and sharply improve operational efficiency.

The Challenge of Limited Warehouse Space

Businesses are under sustained pressure to extract more value from every square foot of their facilities. E-commerce growth and complex supply chains keep pushing inventory levels higher. Physical space doesn’t always keep pace, leading to constrained layouts that waste capacity. The ripple effects show up fast: goods become harder to locate, picking takes longer, and process bottlenecks drag down productivity. Left unchecked, these issues cut into margins and weaken customer satisfaction. Demand for solutions that store more in less space has never been higher.

Understanding High-Density Pallet Racking Solutions

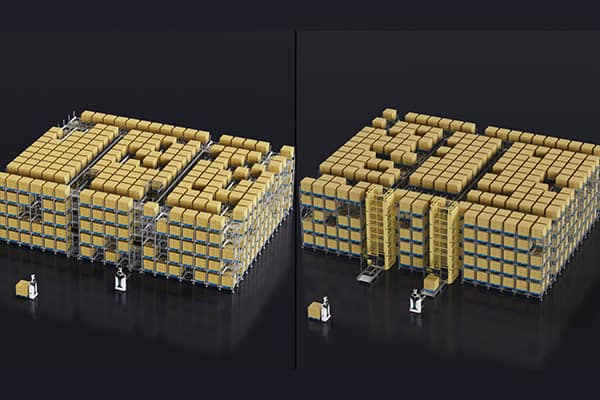

High-density pallet racking systems are built to maximize capacity by reducing or removing aisles. The focus shifts to cubic utilization rather than instant access to every pallet. Pallets are stored in deep lanes, side-by-side or back-to-back, to pack more units into the same footprint. This approach is a strong fit for operations handling large volumes of similar SKUs.

1. Static High-Density Options

Static high-density racking can be configured to match specific workflows. Drive-in and drive-through racking let forklifts enter the structure and place pallets several deep, ideal for large quantities of homogeneous products. Push-back racking uses nesting carts on inclined rails, enabling storage from 2 to 6 deep with retrieval from the same aisle. Pallet flow racking, or gravity flow, relies on inclined rollers to move pallets from the loading side to the picking side, ensuring FIFO stock rotation. Each static option delivers major space savings compared to conventional selective racking.

2. Dynamic Automated High-Density Systems

Dynamic automated high-density systems push storage efficiency higher by integrating advanced robotics and control systems. Specialized equipment moves pallets within the racking, cutting manual touches and tightening space utilization. Automated pallet shuttle systems, such as Zikoo’s R-bot Four-Way Shuttle, operate independently in deep lanes, transporting pallets with precision and speed. This automation lifts both storage density and throughput. The R-bot, with its slim 125 mm body and up to 1.5-ton load capacity, offers flexible four-way movement and intelligent autonomous handling. It can work in concert with multiple units, raising the level of warehouse automation. For example, integrating the R-bot with the H-bot vertical bidirectional shuttle creates a six-way shuttle system, adaptable to diverse palletized goods storage and picking scenarios. This combination provides a robust four-way shuttle system for dense storage.

We specialize in providing cutting-edge solutions for high-density storage. Learn more about our offerings by reading 《Smart Storage Revolution: Comprehensive Overview of Four-Way Shuttle Systems for Automatic 3D Warehouses》.

| Model Options | Weight (kg) | Rated Load (kg) | Dimensions (L×W×H mm) | Pallet Sizes Supported (mm) | Empty Speed (m/s) | Loaded Speed (m/s) | Battery (V/Ah) | Continuous Operation (hours) |

|---|---|---|---|---|---|---|---|---|

| Standard (R1200B) | 270 | 1200 | 1000 × 972 × 125 | 1200 × 800–1000 | 1.6 | 1.2 | 51.2/40 or 30 | 8 |

| American (R1200A) | 265 | 1200 | 1192 × 840 × 125 | 1016 × 1219 | 1.6 | 1.2 | 51.2/40 or 30 | 8 |

| Japanese (R1500J) | 270 | 1500 | 1192 × 900 × 125 | 1100 × 1100 | 1.6 | 1.2 | 51.2/40 or 30 | 8 |

| Heavy-duty (R1500B) | 275 | 1500 | 1192 × 972 × 125 | 1200 | 1.6 | 1.2 | 51.2/40 or 30 | 8 |

| Heavy-duty Large Pallet (R2000B) | 400 | 2000 | 1250 × 1300 × 150 | 1400 | 1.35 | 1.0 | 51.2/40 or 30 | 7 |

Key Benefits of Maximizing Warehouse Storage

High-density pallet racking delivers more than extra capacity. By fitting more into the same footprint, businesses can defer or avoid expansions or new builds, which directly translates into significant cost savings for warehouse operations. Better organization and shorter travel paths for material handling equipment raise operational efficiency. Automated systems, like those we provide, cut labor requirements and boost throughput, accelerating ROI on high-density racking. Inventory control also improves, as dedicated lanes and automated tracking reduce errors and sharpen stock accuracy. These systems suit industries with high volumes of goods, including e-commerce, food and beverage, and manufacturing.

Integrating Automation for Ultimate Density and Efficiency

Zikoo Smart Technology Co., Ltd. takes high-density racking from static setups to dynamic, high-throughput systems using advanced pallet-to-person robotics and PTP Smart Warehouse Software. Together, they create complete automated storage and retrieval system solutions that reset performance expectations. Our approach delivers smooth, coordinated operation, optimizing every aspect of material flow and inventory management.

1. Zikoo Robotics Enhancing Density

Our robotic solutions are built to maximize storage density and throughput. The U-bot Omnidirectional Stacker Robot can navigate aisles as narrow as 2100 mm and lift to 8 meters, significantly expanding vertical utilization. The R-bot Four-Way Shuttle, as noted, handles deep-lane storage with flexible, intelligent movement. When paired with H-bot High-Speed Elevators as vertical transportation hubs, these robots form a sophisticated six-way shuttle system. The result is a true three-dimensional warehousing network, enabling very high storage density and rapid pallet movement. These robots help ensure every available cubic inch of warehouse space gets used well.

To discover how our solutions can revolutionize your logistics, explore 《Six-Way Shuttle: Empowering Industries to Embrace Smart Warehousing》.

2. The Power of PTP Smart Warehouse Software

The PTP Smart Warehouse Software suite (WMS/WES/WCS/RCS) is the intelligence behind our hardware. This unified software platform orchestrates all robotic movements, manages inventory, and optimizes workflows in real time. The Warehouse Management System (WMS) handles inventory tracking and order fulfillment. The Warehouse Execution System (WES) optimizes task allocation and workflow sequencing. The Warehouse Control System (WCS) directly controls automated equipment for tight coordination. Finally, the Robot Control System (RCS) manages individual robot navigation and task execution. This integrated software delivers precise control, real-time inventory management, and dynamic path planning, improving efficiency and adaptability in complex warehouse environments.

Choosing the Right High-Density System for Your Business

Selecting the right high-density pallet racking system takes a careful look at multiple factors. Start with inventory characteristics, such as SKU variety, pallet dimensions, and turnover rates. Match system design to required throughput for inbound and outbound flows. Budget and future growth plans should guide choices as well. We recommend working with intelligent warehousing experts to assess current operations and roadmap targets. That ensures the solution aligns with your objectives, maximizing efficiency and ROI. A tailored warehouse layout optimization strategy is key to long-term success.

Call to Action

Ready to make better use of your warehouse space and boost efficiency? Contact Zikoo Smart Technology Co., Ltd. today for a personalized consultation on high-density pallet racking systems and integrated automation solutions. Our experts are here to help you design the optimal storage strategy for your business needs.

Email: [email protected]

Phone: (+86)-19941778955

FAQs

What is the primary advantage of high-density pallet racking over selective racking?

The primary advantage is significantly increased storage capacity within the same footprint. High-density systems minimize aisle space, allowing for more pallets to be stored, which is vital for maximizing warehouse space. This leads to better utilization of existing facilities and can delay or eliminate the need for costly expansions.

Are high-density racking systems suitable for all types of inventory?

While highly effective for many, high-density systems are best suited for inventory with a high number of pallets per SKU (Stock Keeping Unit) and lower selectivity requirements. Systems like pallet flow are great for FIFO (First-In, First-Out), while drive-in/push-back are better for LIFO (Last-In, First-Out). Zikoo’s automated solutions can enhance flexibility and adaptability for a wider range of inventory types.

How do Zikoo’s robotics enhance high-density pallet racking?

Zikoo’s robotics, such as the R-bot Four-Way Shuttle and U-bot Omnidirectional Stacker Robots, automate the movement and storage of pallets within high-density systems. This drastically improves throughput, reduces labor costs, enhances safety, and allows for even greater space utilization by enabling higher stacking and deeper lanes. Our robots provide precise and efficient handling, integrating cleanly with racking structures.

What is the typical ROI for investing in high-density racking and automation?

The ROI can vary significantly based on factors like warehouse size, labor costs, and inventory volume. However, businesses often see returns through reduced real estate costs, lower operational expenses, improved inventory accuracy, and increased throughput. Automated systems, like those offered by Zikoo, often accelerate this ROI due to substantial labor and efficiency gains and improved competitiveness.

What safety considerations are important for high-density racking?

Safety is paramount. Key considerations include proper installation by certified professionals, regular inspections, adherence to load capacities, clear aisle markings, and adequate training for operators. With automated systems from Zikoo, many manual handling risks are mitigated, further enhancing warehouse safety by reducing human interaction with heavy loads in confined spaces.