When I walk a site during peak season and see forklifts queuing down a 50-meter aisle, it’s a reminder of how quickly manual pallet handling hits its limits. Large distribution centers need every cubic meter and every minute to work harder—especially with labor pressure, tighter safety standards, and SKU proliferation. In this piece, I’ll lay out how automated pallet storage—four-way shuttles, vertical shuttles, omnidirectional stackers, and collaborative AMR systems—solves those bottlenecks, where each technology fits, the measurable gains you can expect, and the practical steps to selecting and deploying the right solution. It’s the path we use to turn conventional warehouses into high-performance, resilient logistics hubs.

Why Large-Scale Distribution Centers Need Automated Pallet Storage

Large-scale distribution centers anchor global supply chains, but they’re constantly wrestling with real-world constraints. Manual pallet storage and retrieval is slow, labor-heavy, and susceptible to human error, which compounds during peak periods. Valuable vertical space often goes underused, aisles become choke points, and rising labor costs—plus ongoing shortages—make legacy methods harder to justify. Meanwhile, faster fulfillment cycles and expanding SKU ranges demand agility that manual processes struggle to deliver. Automated pallet storage systems address these pain points head-on: they increase storage density, accelerate processing, and cut operating costs. Adopting automation isn’t just an incremental upgrade—it’s a step-change toward a more resilient, responsive supply chain.

Understanding Automated Pallet Storage Systems for Distribution Centers

Automated pallet storage systems bring together robotics, software, and engineered infrastructure to streamline how palletized goods are stored and retrieved. From e-commerce to manufacturing and cold chain, we’re seeing broad adoption because each technology family can be tuned to specific layouts and workflows. Knowing the differences—capabilities, fit, and trade-offs—helps you match the solution to your distribution center’s exact requirements.

1. Exploring Four-Way Shuttle Systems for Dense Pallet Storage

Four-way shuttle systems are a big leap for dense storage. These autonomous robots travel within racking and can move pallets in all four horizontal directions, enabling flexible layouts and significantly higher storage density than traditional approaches. With the ability to reach any pallet from any aisle, they unlock both throughput and operational flexibility.

The Four-Way Pallet Shuttle (R-bot) is an intelligent warehouse robot specifically designed for pallet-to-person dense storage scenarios. Its slim body, only 125 mm thick, and a load capacity of up to 1.5 tons, enable it to operate effectively in high-density environments. The R-bot offers intelligent autonomous handling and multi-shuttle collaborative operation, adapting to various palletized goods storage and picking scenarios. When integrated with vertical shuttles, it forms a six-way shuttle system, further enhancing its capabilities.

R-bot Four-way Shuttle Specifications

| Model | Weight (kg) | Rated Load (kg) | Body Dimensions (L×W×H mm) | Supported Pallet Sizes (mm) | Empty Speed (m/s) | Loaded Speed (m/s) | Battery (V/Ah) | Continuous Operation (hours) |

|---|---|---|---|---|---|---|---|---|

| R1200B | 270 | 1200 | 1000 × 972 × 125 | 1200 × 800–1000 | 1.6 | 1.2 | 51.2/40 or 30 | 8 |

| R1200A | 265 | 1200 | 1192 × 840 × 125 | 1016 × 1219 | 1.6 | 1.2 | 51.2/40 or 30 | 8 |

| R1500J | 270 | 1500 | 1192 × 900 × 125 | 1100 × 1100 | 1.6 | 1.2 | 51.2/40 or 30 | 8 |

| R1500B | 275 | 1500 | 1192 × 972 × 125 | 1200 | 1.6 | 1.2 | 51.2/40 or 30 | 8 |

| R2000B | 400 | 2000 | 1250 × 1300 × 150 | 1400 | 1.35 | 1.0 | 51.2/40 or 30 | 7 |

R-bot application scenarios include dense storage in e-commerce warehouses, cold chain food storage, pharmaceutical constant temperature warehouses, and high-density storage of raw materials and finished products in manufacturing. For specialized environments, such as cold chain, R-bot offers custom solutions with low-temperature batteries and enhanced protection against humidity. These features ensure reliable operation in challenging conditions.

For more information on the advantages of four-way shuttle systems, consider reading Smart Warehousing Choice: Why Four-Way Shuttles Outperform Stacker Cranes.

2. Utilizing Vertical Shuttles for Enhanced Pallet Throughput

Vertical shuttles are the elevator core of multi-level automated storage, rapidly moving pallets between tiers to boost end-to-end throughput. Paired with horizontal shuttles, they create a true 3D material flow that keeps product moving without gaps.

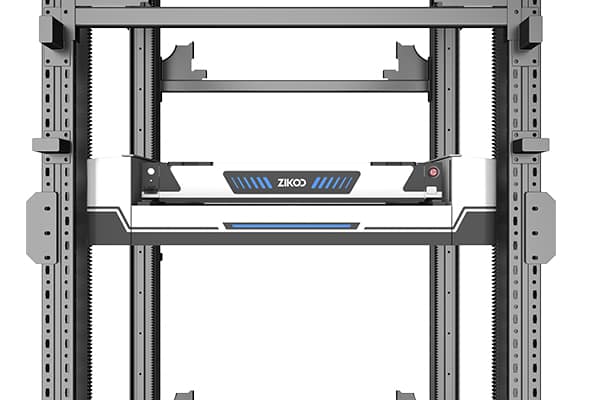

The H-bot Vertical Two-Way Shuttle is designed as a vertical transportation hub in intelligent warehousing systems. It fits into a single storage location, making its layout compact. The H-bot collaborates with the R-bot Four-way Shuttle to establish a three-dimensional warehousing network that spans six spatial directions. This integration dramatically enhances the overall operational efficiency of the warehousing system. H-bot models support various pallet sizes and operate efficiently across a wide temperature range, from -25℃ to 45℃.

H-bot Vertical Bidirectional Shuttle Specifications

| Model | Body Weight (kg) | Body Dimensions (L×W×H mm) | Rated Load (kg) | Supported Pallet Sizes (mm) | Operating Temperature (°C) | Positioning Accuracy (mm) | Empty Speed (m/s) | Loaded Speed (m/s) | Empty Acceleration (m/s²) | Loaded Acceleration (m/s²) |

|---|---|---|---|---|---|---|---|---|---|---|

| H1800B | 345 | 1300 × 1464 × 288 | 1800 | 1200 × 800–1200 | -25 to 45 | ±1 | 1 | 0.5 | 1 | 0.3 |

| H1800A | 325 | 1300 × 1332 × 288 | 1800 | 1016 × 1219 | -25 to 45 | ±1 | 1 | 0.5 | 1 | 0.3 |

| H1800J | 335 | 1300 × 1392 × 288 | 1800 | 1100 × 1100 | -25 to 45 | ±1 | 1 | 0.5 | 1 | 0.3 |

| Heavy-duty Custom | Custom | Custom | Custom | Custom | -25 to 45 | ±1 | Custom | Custom | Custom | Custom |

The primary application scenarios for the H-bot include vertical cargo transfer in high-rack stereoscopic warehouses, urban warehousing centers, and existing warehouse renovation projects. It is also ideal for dense storage scenarios that require improved space utilization. The six-way shuttle solution, formed by combining H-bot with R-bot, significantly enhances overall throughput and efficiency in warehousing systems.

For further insights into integrated shuttle strategies, we recommend From Concept to Deployment: Zikoo’s Integrated Shuttle Strategy.

3. Implementing Omnidirectional Stacking Robots for Narrow Aisle Pallet Handling

Narrow aisle facilities are a different challenge: conventional forklifts need wide aisles and sacrifice capacity. Omnidirectional stacking robots are purpose-built for tight spaces, preserving density without giving up accessibility. With true multi-directional travel, they navigate and stack confidently in aisles down to 2100 mm.

The U-bot Omnidirectional Stacker Robot is an intelligent warehouse robot tailored for pallet-to-person narrow aisle storage. Its U-shaped body design and minimal turning radius of 1370 mm provide exceptional maneuverability. The U-bot can lift pallets up to 8 meters and handle loads of 1000 kg. It also integrates seamlessly with other automated equipment like AMRs and robotic arms for enhanced operational flexibility.

U-bot Omnidirectional Stacking Robot Specifications

| Model | Dimensions (L×W×H mm) | Rated Load (kg) | Self-weight (kg) | Lifting Height (mm) | Minimum Aisle Width (mm) | Driving Positioning Accuracy (mm) | Battery (V/Ah) | Continuous Operation (hours) |

|---|---|---|---|---|---|---|---|---|

| U1045 | 2198 × 1784 × 2100 | 1000 | 3000 | 4500 | 2100 | ±10 | 48 / 210 LiFePO4 | 6–8 |

| U1060 | 2198 × 1820 × 2685 | 1000 | 3300 | 6000 | 2140 | ±10 | 48 / 210 LiFePO4 | 6–8 |

| U1080 | 2198 × 1820 × 3465 | 1000 | 3500 | 8000 | 2140 | ±10 | 48 / 210 LiFePO4 | 6–8 |

U-bot is ideal for narrow aisle high-density storage in e-commerce warehouses, constant temperature storage and picking in pharmaceuticals, and raw material and finished product storage in manufacturing. Its narrow aisle storage solution uses dual laser SLAM hybrid navigation for safe operation and a 3D depth camera for precise pallet positioning.

4. Integrating Collaborative Robot Systems for Hybrid Pallet Picking

Hybrid flows—full pallet (To B) and split-case (To C)—need flexible, well-orchestrated systems. By combining omnidirectional stackers with AMRs, collaborative setups streamline both storage and picking, dynamically assigning work and maintaining smooth material movement.

The U-bot + AMR Narrow Aisle Picking System offers an efficient collaborative solution for these hybrid scenarios. It utilizes an innovative architecture where U-bot handles high-level storage access, and AMRs manage low-level handling and picking. This vertical functional complementarity enhances scenario adaptability, supporting full-category outbound picking for various item sizes through multi-functional workstations.

U-bot + AMR Narrow Aisle Picking System Performance Indicators

| Metric | Value |

|---|---|

| Picking Efficiency | ≥300 pieces/hour |

| Inbound/Outbound Efficiency | ≥80 pallets/hour |

| Storage Density Improvement | >30% |

| Positioning Accuracy | ±10 mm |

| Minimum Aisle Width | 2100 mm |

| Supported SKU Quantity | Up to 10,000 |

This system is particularly beneficial for multi-SKU split-case picking in e-commerce warehouses, raw material and finished product storage in manufacturing, and multi-variety, small-batch storage in pharmaceuticals. Its e-commerce industry solution manages up to 10,000 SKUs with collaborative U-bot and AMR operations, featuring dynamic path planning and multi-functional workstations.

Key Benefits of Automated Pallet Storage in Distribution Centers

Automated pallet storage directly boosts both capacity and productivity. In practice, we often see storage density double or even triple without expanding the building envelope—especially by reclaiming vertical space where real estate is tight. Throughput rises as robots run consistently and accurately, shrinking put-away and retrieval times to meet e-commerce and JIT expectations. Labor costs drop as repetitive handling is automated, while safety improves by taking people out of hazardous, high-traffic, or high-reach tasks.

Inventory accuracy also gets a lift through continuous tracking and real-time integration with warehouse systems, which reduces errors and stockouts. Perhaps most importantly, these solutions scale and reconfigure as demand shifts—ramping for peak season or adapting to new product lines—driving a strong ROI and a more competitive operation overall.

How Zikoo Smart Technology Optimizes Pallet Storage Operations

Zikoo Smart Technology focuses on pallet-to-person robotics that fuse advanced hardware with intelligent software to deliver high-performance, flexible storage systems. Our aim is straightforward: maximize space, accelerate throughput, and preserve adaptability as your business evolves.

Our R-bot Four-way Shuttle, H-bot Vertical Bidirectional Shuttle, and U-bot Omnidirectional Stacking Robot form the backbone of these solutions. R-bot’s four-way mobility and multi-shuttle collaboration enable dense storage across environments from e-commerce to cold chain. H-bot serves as the vertical transport hub and, paired with R-bot, creates a six-way shuttle configuration that lifts system-wide efficiency. U-bot shines in narrow aisles with precise maneuvering and high lift, and it integrates with AMRs for hybrid picking when needed.

On the software side, our PTP Smart Warehouse Software (WMS/WES/WCS/RCS) coordinates real-time inventory, dynamic tasking, and IT integration. That combination—robust robotics plus orchestration software—lets distribution centers unlock exceptional efficiency, scalability, and cost control.

Selecting the Right Automated Pallet Storage Solution for Your Facility

Choosing the right system starts with a clear-eyed assessment and a plan that maps technology to your goals.

- Assess Current Operations: Quantify capacity, throughput, labor costs, and bottlenecks. Catalog pallet sizes, load types, and special conditions (e.g., cold storage).

- Define Future Needs: Forecast growth in volume, SKU breadth, and service levels. Consider expansion and potential shifts in product mix.

- Evaluate Space Constraints: Measure floor area and clear height. Four-way shuttles and omnidirectional stackers can maximize density when space is tight.

- Consider System Scalability and Flexibility: Favor modular designs—combinations of shuttles and vertical lifts scale gracefully with demand.

- Analyze Integration Requirements: Verify clean connections to your WMS, WES, WCS, and RCS. Zikoo’s PTP Smart Warehouse Software is built for end-to-end integration.

- Calculate ROI and Total Cost of Ownership (TCO): Look past capex to operating savings, maintenance, and productivity gains. A detailed model sharpens the business case.

- Partner with an Experienced Provider: Work with a vendor that brings proven tech, customization, and lifecycle support—from design through optimization.

By following this process, you can implement a solution that materially improves efficiency, capacity, and overall performance.

Transform Your Distribution Center with Zikoo Smart Technology

Ready to elevate your distribution center’s capacity and speed? Zikoo Smart Technology delivers automated pallet storage solutions tailored to large-scale operations. Our team will help you design and deploy a system that maximizes space, cuts costs, and increases throughput. Contact us to discuss your requirements and see how our robotics and software can move your operation forward.

Email: [email protected]

Phone: (+86)-19941778955

About the Author

John Smith, a Senior Engineer at Zikoo Smart Technology Co., Ltd., designs and implements advanced automated warehousing solutions. With deep experience in robotics and logistics, John helps warehouses and fulfillment centers boost efficiency, reduce costs, and scale operations using ASRS, 4-way shuttle systems, and intelligent robotic picking. He pairs cutting-edge technology with practical deployment strategies to guide customers through successful smart warehousing transformations.

FAQs

1. What are the main advantages of automated pallet storage over traditional methods?

Automated pallet storage delivers higher storage density, faster throughput, and lower labor costs. It also improves safety by reducing manual handling and enhances inventory accuracy via precise, real-time tracking. Because these systems are scalable and flexible, businesses can respond more effectively to changing demand.

2. How can automated pallet storage systems integrate with existing warehouse management software?

Most systems integrate seamlessly with WMS, WES, and WCS through APIs and standard protocols. This ensures synchronized data and coordinated workflows between automation equipment and your software stack for reliable, real-time operations.

3. What is the typical ROI for implementing automated pallet storage in a large distribution center?

ROI varies with system scope, investment level, and savings, but many sites see strong returns within 2–5 years. Gains typically come from labor reduction, better space utilization, higher throughput, and improved accuracy. A detailed cost–benefit model will provide a precise projection.

4. Can automated pallet storage systems handle various pallet sizes and types?

Yes. These systems are designed to support a broad range of pallet standards and formats. For example, the R-bot Four-way Shuttle accommodates standard, American, and Japanese dimensions, along with heavy-duty and larger pallets. Custom configurations are available for unique requirements.

5. How do automated pallet storage systems improve worker safety and reduce labor costs?

By automating heavy lifts and high-traffic movements, these solutions remove operators from risk-prone tasks and reduce injury exposure. At the same time, they lower labor demand for repetitive work, allowing teams to shift toward higher-value roles and operate with a leaner, more specialized workforce.