In the age of intelligent logistics, industries such as pharmaceuticals, food, and manufacturing are demanding more from their warehousing infrastructure: faster deployment, greater flexibility, and higher storage density. Traditional automation tools—like stacker cranes and fixed conveyor systems—often fall short in dynamic, multi-SKU, and high-frequency throughput environments.

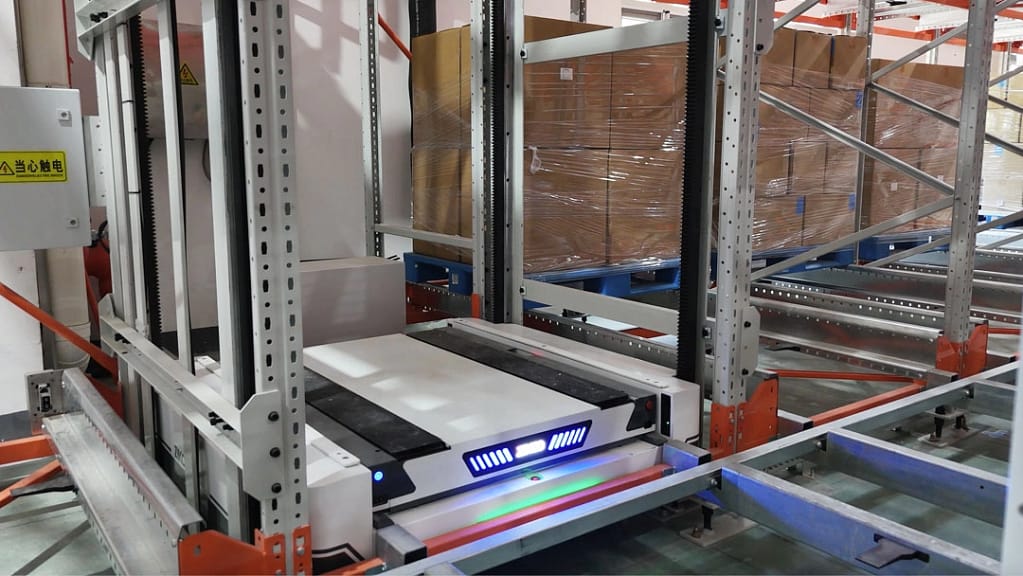

Enter Zikoo Robotics, a global innovator in pallet warehouse automation, with its breakthrough solution: the Six-way shuttle system. Built on the synergy of two robotic components—R-bot (Four-way shuttle) and H-bot (vertical two-way shuttle)—this system achieves full six-directional movement, enabling true Automatic 3D warehouse capabilities.

Unlike traditional fixed-path automation, the Six-way shuttle system eliminates the need for static lifts or conveyor routing. It enables agile navigation across all axes—up/down, left/right, and front/back—making it ideal for Dense storage scenarios with minimal aisle requirements. It’s a future-ready solution for businesses that require highly adaptive Pallet Smart Warehouse systems.

✅ Key Advantages:

Robot replaces traditional machines: flexible robotic architecture replaces rigid infrastructure.

Rapid deployment: standard modular components allow quick on-site assembly and scaling.

Seamless flow: intelligent RCS software enables real-time coordination of multi-robot systems.

High ROI: reduces capital investment, shortens delivery cycles, and minimizes downtime.

Zikoo Robotics stands out among global 3D warehouse manufacturers and Four-way shuttle providers for its dedication to product standardization and operational flexibility. With successful deployments across Europe, Asia, and the Middle East, Zikoo continues to redefine intelligent warehousing for the modern supply chain.

If you’re planning to build the next-generation Intelligent Logistics infrastructure, the Six-way shuttle system from Zikoo Robotics is your strategic advantage.

Keywords: